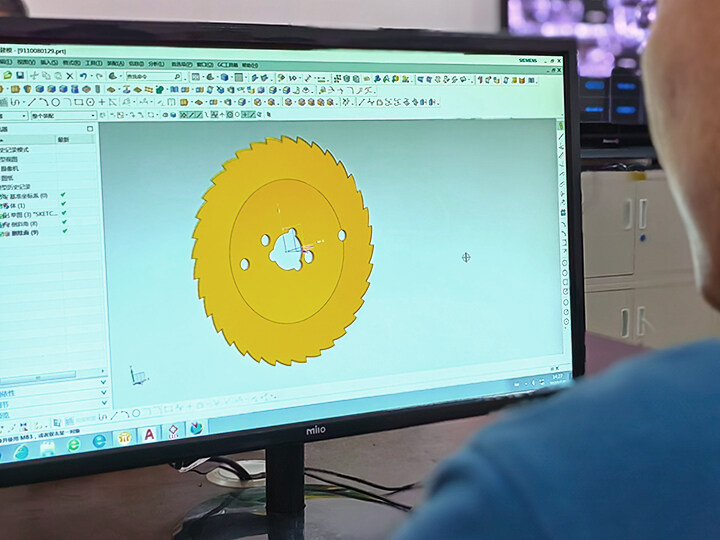

Product Design

From the initial design of a product. We give it a unique ID number in our system, thus enabling full lifecycle identification and control.

Each drawing is carefully checked by the LUK engineering team, then signed by the customer and us as a standard for production and inspection.

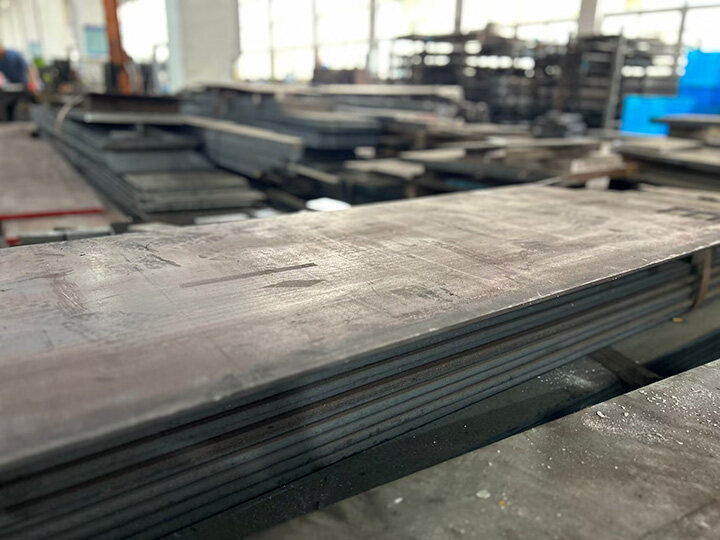

Raw Material

Only steel from selected and well-known steelworks can be used to produce LUK knives. And a quality assurance certificate for each batch of steel is a must.

After the steel arrives at LUK plant, we perform metallographic analysis and chemical composition test in our in-house laboratory equipped with advanced testing instruments. Third-party lab tests can also be carried out when it is necessary. All these are taken to ensure the quality of the material.

This strict standard is followed for all kinds of steel we use. Such as high grade martensitic stainless steel, tool steel, high speed steel, powder metal steel, and ultra-fine particle tungsten carbide.

Heat Treatment

As a professional machine knife manufacturer. LUK understands the importance of heat treatment in the production of blades.

This core process is carried out in LUK’s own factory, under the supervision of our heat treatment engineers with more than 30 years of experience.

The unique heat treatment process ensures a homogeneous metallographic distribution and a stable structure of the knife, resulting in a suitable hardness and excellent durability.

Machining & Grinding

Every step in our manufacturing is well designed by LUK engineering team based on decades of experience in machine knife production.

State-of-the-art CNC machines and automated equipment are extensively used in our manufacturing process, combining with traditional craftsmanship and our unique machining and grinding technology, to deliver the most accurate and durable cutting tools.

Quality Control

The First Article Inspection. In-Process Quality Control, Final Quality Control, as well as the operators’ frequent self- inspections, constitute a complete inspection procedure and provide a real and valid data base for our daily quality reports.

From drawing to process, from raw material to final product, all quality records can be traced in LUK’s system.

Logistics Service

With 30 years of international trade practice, LUK has accumulated rich experience and efficient logistics channels. Leveraging more than300 logistics routes, we support our dear customers with most competitive transportation methods and freight costs that match their countries and regions, while guaranteeing timeliness.

Meanwhile. LUK team is familiar with the policies of various countries, and can quickly handle customs clearance and other processes to facilitate quick receipt of goods for our customers.

Copyright © 2024 LUK Knives