Recycling is an important part in circular economy. Recyclers need to handle a mass of plastics, rubber, paper, metals and other reusable materials each day. And the working conditions are extremely tough because of high temperature, humidity, alternate heat and cold, and impurities. Under these conditions, knives may meet problems such as cracks, breakage, short-wear life, longer down time etc.

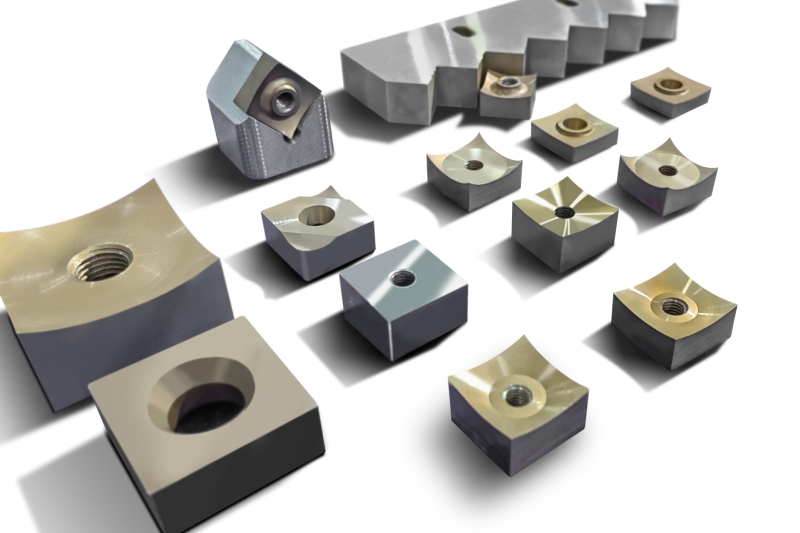

Our expert team helps the customers find proper and quality steel for blades as per different cutting application. And appropriate heat treatment is carried out in-house. These ensure homogeneously distributed hardness and great red hardness property of LUK knives. Providing better toughness and wear-resistance. In addition, we use high precision CNC equipment in machining and grinding to guarantee accurate dimensions. Thus, LUK knives are very sharp without burr that not only deliver better cutting quality, but also last longer.

By using LUK knives, the recyclers get rid of cracks, breaks and short wear life of knives on their recycling machines. That’s why LUK recycling knives are well received by numerous customers around the world.

Copyright © 2024 LUK Knives