XJL adheres to the principle of T.O.R.S. (Top-notch quality, Timely delivery, Reasonable price, and Sincere service) to complete every customer’s order.

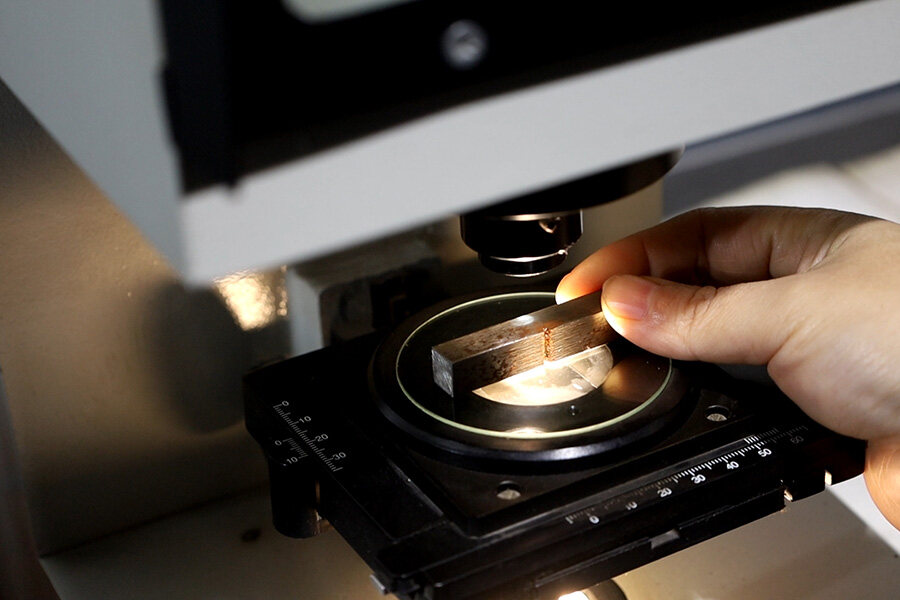

To maintain our highest quality, in terms of hardware, we have introduced advanced production equipment and built a high-quality casting production line; in terms of software, we use ERP production management software to ensure product traceability; we are also equipped with advanced machining equipment to meet Customers’ one-stop purchasing needs for casting + machining; attaching great importance to product testing, starting from raw materials and running through each production stage to ensure consistent high quality of castings.

XJL is your premier resource for specialty investment precision castings.

To have more information, please do not hesitate to contact.