Key Materials and Their Roles in Pultrusion Manufacturing Process

The pultrusion process is a method of molding in which continuous untwisted roving, mats, tapes, or cloths soaked in glue are drawn and extruded through

The pultrusion process is a method of molding in which continuous untwisted roving, mats, tapes, or cloths soaked in glue are drawn and extruded through

With the rapid advancement of technology, the application of new materials has become increasingly widespread. Fiberglass profiles are one such exemplary representation. This innovative material,

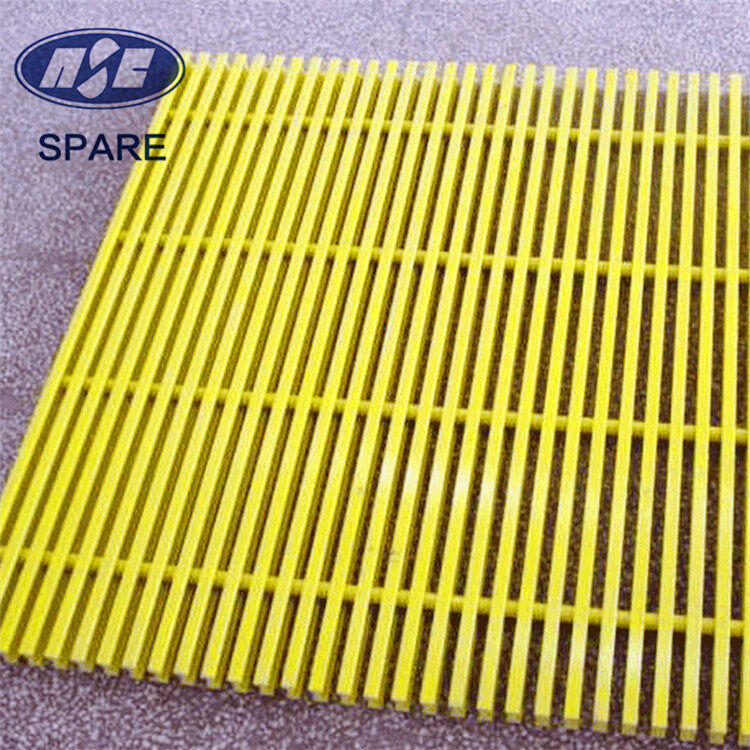

The pultruded grating is formed by pultruding “I” and “T” shaped profiles as load-bearing bars, using a sawtooth-shaped connection with transverse rods. Fiberglass pultruded grating

An increasing number of architects, engineers, and builders are incorporating fiberglass pultrusion into various construction and infrastructure projects, a trend that is accelerating due to

The process of pultrusion for fiberglass reinforced plastic (FRP) products can be briefly divided into three steps: impregnation, molding, and curing/cooling. It is an automated

Fiber Reinforced Polymer (FRP) is a composite plastic made from a matrix or adhesive reinforced with fiber material. Therefore, the FRP process requires two steps: