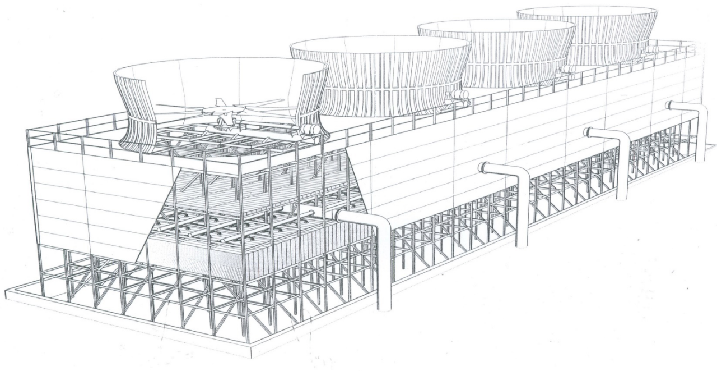

The rapid increase in industrial water consumption due to national economic development has made it imperative to promote the use of cooling towers and industrial and refrigeration water recycling in order to save water, protect the environment and reduce energy consumption. Cooling towers are large heat exchangers primarily used in power plants and manufacturing plants to cool water, which in turn cools the equipment necessary for daily operations.

During operation, the structural materials used in cooling towers must withstand various environments, including chemical and biological attacks and harsh conditions. Pultruded glass fiber reinforced plastic (GFRP) profiles are an ideal choice for cooling tower structural parts due to their high strength, light weight, and corrosion resistance, which are inherent properties of FRP. Furthermore, pultrusion and other FRP production processes, such as hand paste or RTM, are highly economical and provide superior material performance.

- The use of pultruded GFRP as a structural material in cooling towers offers significant advantages over wood, concrete, and steel.

- Unlike wood, the absence of a substrate for microorganisms in glass fibers and resins eliminates biomass corrosion in GFRP.

- GFRP exhibits superior chemical resistance compared to steel and concrete materials.

- GFRP is also lightweight when compared to structural wood, steel, and concrete.

- GFRP requires no maintenance and damaged parts are easily replaceable, making it a highly practical and cost-effective material choice for cooling tower construction.

In 2015, the Ningcoal project’s cooling tower began utilizing FRP pultruded material as the primary support structure. The Shenhua Ningxia Coal Group Coal Indirect Liquefaction Project, deemed the “No.1 Project” by the Ningxia Autonomous Region, is the sole large-scale coal-to-oil demonstration project in China. Located in Ningdong Town Energy Chemical Base, Lingwu City, Ningxia, China, the project’s overall investment totals RMB 55 billion and is designed to yield 4 million tons of oil products annually. The cooling towers for the first and second circulating water fields for the 4 million tons/year coal indirect liquefaction project consist of FRP towers, constructed utilizing pultruded FRP profiles supplied by Spare. The project’s 60 cooling towers each incorporate roughly 45 tons of FRP pultruded profiles in their design.