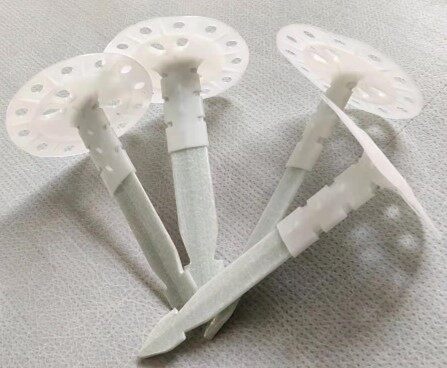

Spare has developed and manufactured a significant component, the FRP connector, for sandwich wall construction. This connector is utilized to link the concrete slabs on both sides of the insulation slab and is primarily intended to resist lifting and shear forces between the inner and outer leaf walls. During concrete pouring, ABS engineering plastic rings are utilized to fix the connectors’ position. Spare has demonstrated its capacity to produce FRP connectors on a large scale and has supplied over 13 million to various firms in China, including Vanke Beijing region, Anhui Hailong Company of China Construction Group, Beijing General Housing, Yuanda Housing, Zhongnan Construction Group, Shanghai Construction, Shanghai Urban Construction, and Shanghai General Housing, among others. In general, Spare’s FRP connector is a critical and widely used component in sandwich wall construction.

FRP joints for composite insulation integrated panels

The figure on the right depicts an exterior wall insulation connector used for composite insulation integrated panels. Compared to commonly used all-plastic anchor bolts or anchor nails, this FRP connector exhibits excellent mechanical properties such as longitudinal tensile strength, superior pull-out resistance, and stable anchoring performance. In comparison to steel anchor bars, the pull-out resistance is essentially the same as that of the steel bar under the same anchoring length. However, the FRP connector will not rust and has excellent thermal insulation properties.