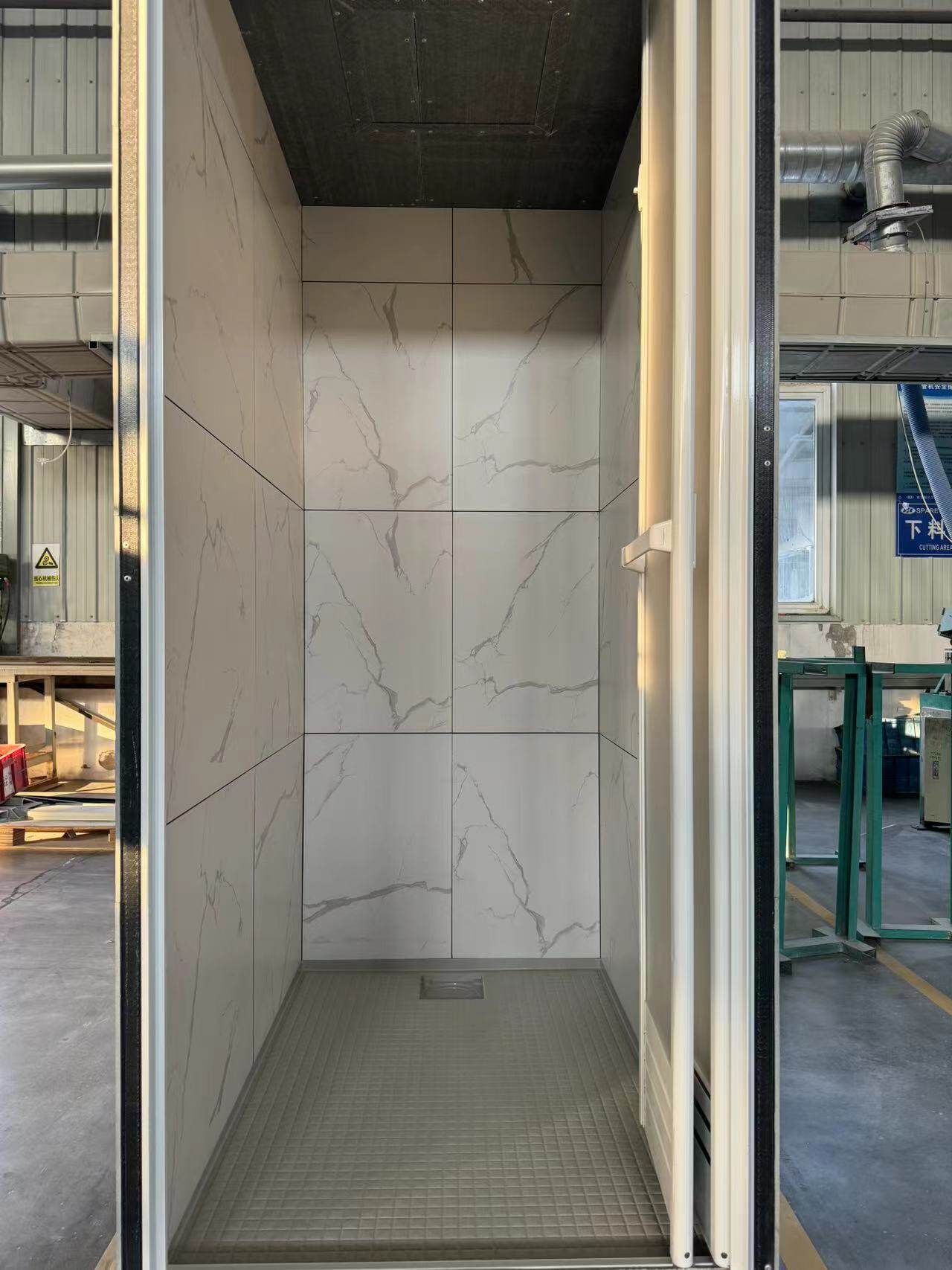

Application of FRP Materials

FRP, or Fiber Reinforced Plastic, is a high-performance composite material made from fiber-reinforced materials and resin. It’s primarily used in the wall systems, chassis systems, and ceiling systems of bathrooms. FRP’s light weight, corrosion resistance, flexible design, and easy installation not only meet the safety, usability, and durability of structures, but also avoid leakage risks, extend lifespan, and offer customizable designs to meet diverse customer needs, enhancing customer value.

Characteristics of Prefabricated Bathrooms

Prefabrication and Modularization: Standardized design, modular production, and assembly-style installation. All systems of prefabricated bathrooms are standardized and mass-produced in factories, then assembled on-site.

Design Flexibility: Despite being prefabricated, these bathrooms still offer a variety of design choices to meet personalized customer needs.

Construction Efficiency: Major components are pre-assembled in factories, and on-site assembly takes just a few hours, significantly shortening the overall construction period.

Environmental Friendliness: The on-site installation process reduces traditional wet operations, avoiding construction waste, dust, and noise pollution, and aligns with green building concepts.

Cost-Effectiveness: Prefabricated bathrooms reduce quality risks like water leaks and maintenance needs, making their overall lifecycle cost lower than traditional methods.

Application Scenarios

Hotel Projects: With tight opening schedules, the rapid installation of prefabricated bathrooms significantly shortens the total project duration.

Hospital Construction: Hospitals have high standards for hygiene and safety. Prefabricated bathroom units completed in controlled factory environments ensure high hygiene standards.

Large-scale Residential Developments: In large residential projects, uniform and standardized prefabricated bathrooms significantly improve construction efficiency while ensuring quality consistency in each unit.

Advantages of FRP Materials

Lightweight and Strong: The high strength and low density of FRP materials make bathroom units easier to transport and install while maintaining necessary structural stability.

Corrosion Resistance: FRP’s resistance to various chemicals makes it particularly suitable for humid bathroom environments.

Customization and Processing Ease: FRP materials can be easily molded according to design needs, offering more design freedom.

Insulation Properties: FRP materials have good insulation properties, enhancing the safety of bathroom units.

Long-term Durability: The durability of FRP materials ensures a long lifespan of bathroom units, reducing the need for maintenance and replacement.

Prefabricated bathrooms, especially those using FRP materials, represent an important trend in the construction industry. They not only improve the efficiency and quality of construction projects but also demonstrate the limitless possibilities of bathroom design with innovative material applications. As technology advances, prefabricated bathrooms are expected to be increasingly used in various construction projects, bringing more innovations to modern architecture.