Customization of FRP profiles

1. Cross-sectional customization: Customize and produce suitable products according to customers’ requirements or drawings.

2. Performance customization: Customize suitable performance products according to the environment of use or special requirements of customers, mainly the choice of resin, flame retardant and UV resistance, and other performance choices.

3. Surface customization: the use of different surface felts or no surface felts, resulting in differences in the appearance of the surface.

4. Post-processing customization: perforation, assembly, etc.

Customization process

Consultation details—–Product drawing is determined—–Mold customization.—–Product production—–Shipping—–After-sales service.

Our pull rings offer many advantages. They are lightweight, strong, have excellent dimensional stability, electrical and thermal insulation, corrosion resistance and electromagnetic transparency, and are consistently colored.

"*" indicates required fields

The Beijing Vanke Jade West Lake residential project comprises 20 small high-rise buildings, with a total roof area of 12,000 square meters. The roofing material

The rapid increase in industrial water consumption due to national economic development has made it imperative to promote the use of cooling towers and industrial

Spare has developed and manufactured a significant component, the FRP connector, for sandwich wall construction. This connector is utilized to link the concrete slabs on

The FRP cooling tower utilized in the Shanghai Laogang Renewable Energy Utilization Center Phase II Project was designed by SPX Company. It is a mechanical

The apron, situated atop the Tres Cruces Hospital in Bilbao, Spain, spans 3 meters and can accommodate helicopters weighing up to 6 tons (13,200 lbs).

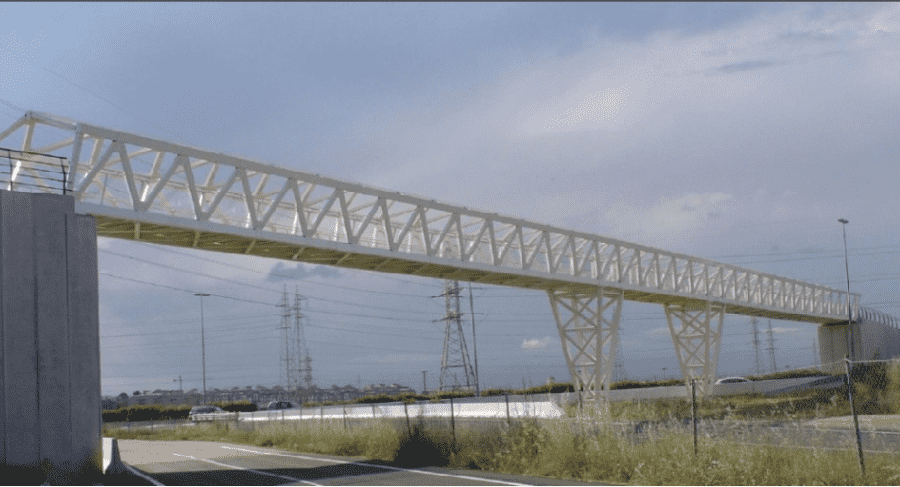

Spare’s lightweight and high-strength FRP materials present an optimal solution for bridge deck applications. These panels possess a longer life cycle than their timber, concrete,