Pultruded fiberglass channels are produced by a pultrusion process in which reinforcing fibers and liquid resin are combined to form fiber-reinforced plastic (FRP), which is then molded into channels of various sizes and shapes to meet specific requirements.

The continuous length of the reinforced fibers gives these lightweight channels exceptional tensile strength. They can be used as structural pultrusion or pultruded electrical shapes.

When you work with our team of expert engineers in the production process, you can adjust the resin system and glass content and change the composite matrix to produce pultruded fiberglass channels with different properties such as high strength, high temperature resistance, flame resistance, track resistance and corrosion resistance.

In addition, pigments can be added during the pultrusion process to produce channels in a variety of colors, and UV-resistant treatments can be used to increase the durability of the channels – making them ideal for outdoor applications.

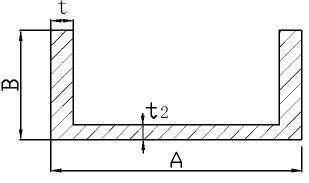

| channel | S/N | A | B | t/t2 | Number | |

|

1 | 206 | 272 | 3 | C-0794 | |

| 1 | 300 | 90 | 15/15 | C-0079 | ||

| 2 | 280 | 70 | 12/12 | C-0094 | ||

| 3 | 254 | 69.85 | 12.7/12.7 | C-0651 | ||

| 4 | 203.2 | 55.56 | 6.35/6.35 | C-0650 | ||

| 5 | 203.2 | 55.56 | 9.52/9.52 | C-0639 | ||

| 6 | 200 | 80 | 4/6 | C-0602 | ||

| 7 | 200 | 60 | 9.5/9.5 | C-0105 | ||

| 8 | 200 | 60 | 8 | C-0419 | ||

| 9 | 193 | 30 | 3/3 | C-0108 | ||

| 10 | 140 | 80 | 14 | C-0777 | ||

| 11 | 140 | 50 | 6/6 | C-0372 | ||

| 12 | 180 | 60 | 8/8 | C-0093 | ||

| 13 | 152.4 | 41.28 | 6.35/6.35 | C-0631 | ||

| 14 | 152.4 | 42.9 | 9.5/9.5 | C-0102 | ||

| 15 | 152.4 | 39.9 | 9.5/9.5 | C-0101 | ||

| 16 | 150 | 75 | 8/6 | C-0466 | ||

| 17 | 150 | 50 | 6/6 | C-0090 | ||

| 18 | 140 | 60 | 2.5 | C-0842 | ||

| 19 | 139.7 | 38.1 | 6.35 | C-0721 | ||

| 20 | 139.7 | 38.1 | 4.76/4.76 | C-0638 | ||

| 21 | 127 | 45 | 6.35/6.35 | C-0100 | ||

| 22 | 120 | 60 | 8/8 | C-0078 | ||

| 23 | 120 | 60 | 5/5.2 | C-0467 | ||

| 24 | 120 | 65 | 10/15 | C-0545 | ||

| 25 | 103 | 60 | 6.35/6.35 | C-0091 | ||

| 26 | 101.6 | 28.6 | 6.35/6.35 | C-0099 | ||

| 27 | 100 | 50 | 10 | C-0696 | ||

| 28 | 100 | 50 | 6/6 | C-0089 | ||

| 29 | 96.5 | 85 | 5/5 | C-0568 | ||

| 30 | 90 | 45 | 5.2/5.2 | C-0394 | ||

| 31 | 88.9 | 38.1 | 4.76/4.76 | C-0630 | ||

| 32 | 87 | 33 | 3.3/3.3 | C-0082 | ||

| 33 | 85 | 85 | 10 | C-0678 | ||

| 34 | 85 | 30 | 6/3.65 | C-0334 | ||

| 35 | 84.5 | 33.3 | 3.3 | C-0083 | ||

| 36 | 84 | 30 | 5/3.3 | C-0080 | ||

| 37 | 84 | 30 | 5/3.45 | C-0085 | ||

| 38 | 84 | 30 | 5/4.3 | C-0086 | ||

| 39 | 80 | 45 | 3.5/3 | C-0787 | ||

| 40 | 80.5 | 30 | 3 | C-0768 | ||

| 41 | 80 | 30 | 3.3/3.3 | C-0314 | ||

| 42 | 80 | 30 | 3.1/2.6 | C-0389 | ||

| 43 | 80 | 30 | 3/3 | C-0396 | ||

| 44 | 76.2 | 25 | 6.35/6.35 | C-0077 | ||

| 45 | 75 | 35 | 5/5 | C-0454 | ||

| 46 | 75 | 50/30 | 2.5 | C-0666 | ||

| 47 | 60 | 60 | 4.8/4.8 | C-0104 | ||

| 48 | 40 | 60 | 4 | C-0861 | ||

| 49 | 60 | 35 | 3 | C-0772 | ||

| 50 | 55 | 70 | 5/5 | C-0084 | ||

| 51 | 55 | 37 | 4/4 | C-0281 | ||

| 52 | 50 | 30 | 4/4 | C-0107 | ||

| 53 | 51 | 25 | 3 | C-0767 | ||

| 54 | 46 | 40*30 | 3/3 | C-0490 | ||

| 55 | 44.5 | 31.3 | 3.3 | C-0081 | ||

| 56 | 44 | 28 | 3.3/2.6 | C-0313 | ||

| 57 | 44 | 28 | 3.1/2.5 | C-0390 | ||

| 58 | 42 | 42 | 3 | C-0166 | ||

| 59 | 42 | 24 | 5 | C-0167 | ||

| 60 | 41.5 | 41.5 | 3.5/3.5 | C-0103 | ||

| 61 | 44 | 30.2 | 3/3 | CX-0544 | ||

| 62 | 40 | 15 | 4/4 | C-0092 | ||

| 63 | 40 | 15 | 3/3 | C-0538 | ||

| 64 | 38.1 | 38.1 | 6.35 | C-0728 | ||

| 65 | 38 | 25 | 2/2 | C-0477 | ||

| 66 | 37 | 20 | 2.5 | C-0332 | ||

| 67 | 35 | 15 | 2 | C-0838 | ||

| 68 | 25 | 30 | 3/3 | C-0095 |

Pultruded fiberglass channels will not mold, scale, rot or rust, and due to their unique properties, outperform many traditional materials such as wood, steel and aluminum.

Corrosion and chemical resistance. FRP is resistant to a wide range of chemicals, unaffected by oxidation and corrosion, eliminating the costs associated with painting or galvanizing.

Lightweight but strong: Pultruded fiberglass channels can be 30% lighter than aluminum and 70% lighter than steel without sacrificing strength. In particular, it offers exceptional dimensional stability and much higher tensile strength than steel in a pound-for-pound comparison.

Flexible and impact resistant. FRP does not deform permanently under working load, and the load is distributed by a glass mat to prevent surface damage.

Non-conductive: Pultruded fiberglass channels are electrically and thermally non-conductive, making them a safe choice for many applications.

Cost-effective: Pultruded fiberglass channels are economical to transport and easy to handle (e.g., cut and formed with simple tools), reducing the overall cost of any project.

Highly durable: Because they do not deteriorate or rust, pultruded fiberglass channels have a long life cycle, with low maintenance requirements and costs.

EMI/RFI transparent: The non-magnetic electromagnetic transparency makes pultruded fiberglass channels ideal for many special applications where metal parts can cause interference.

Sustainability: Pultruded FRP products are energy efficient to manufacture, transport and install, requiring less heat, generating less waste and causing less pollution. In addition, FRP can have a life cycle of 75-150 years and can be recycled or retrofitted into other plastic-based products – making it an eco-friendly option for many industries (e.g., construction, manufacturing).

Applications of pultruded fiberglass channels

"*" indicates required fields

The rapid increase in industrial water consumption due to national economic development has made it imperative to promote the use of cooling towers and industrial

The FRP cooling tower utilized in the Shanghai Laogang Renewable Energy Utilization Center Phase II Project was designed by SPX Company. It is a mechanical

The Beijing Vanke Jade West Lake residential project comprises 20 small high-rise buildings, with a total roof area of 12,000 square meters. The roofing material

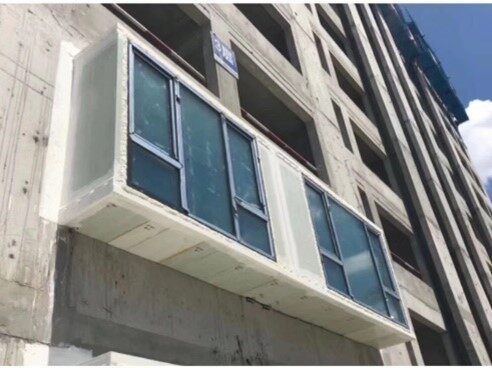

The FRP assembled floating windows produced by Changchun Parkview incorporate hollow web panels manufactured by Spare. The use of these panels allows for easy and

Spare has developed and manufactured a significant component, the FRP connector, for sandwich wall construction. This connector is utilized to link the concrete slabs on

The Rama 8 Bridge, situated over the Chao Phraya River in Bangkok, the capital of Thailand, was completed in 2001 and has since been operational.