FRP mould pressing is one of the oldest and most dynamic molding methods in the production of composite materials. It is a method in which a certain amount of premixed or prepreg material is added to a metal pair of molds and cured by heating and pressure.

The main advantages of the molding process are

①High production efficiency, easy to realize specialized and automatic production.

②High dimensional accuracy and good repeatability of the product.

③Smooth surface, no need for secondary finishing.

④capable of forming products with complex structures in one go.

⑤The price is relatively low because of mass production.

"*" indicates required fields

The corridor bridge connecting the old and new pavilions of Tsinghua University Civil Engineering Department was designed with Spare GFRP panels as permanent formwork for

Spare has developed and manufactured a significant component, the FRP connector, for sandwich wall construction. This connector is utilized to link the concrete slabs on

The FRP cooling tower utilized in the Shanghai Laogang Renewable Energy Utilization Center Phase II Project was designed by SPX Company. It is a mechanical

The Beijing Vanke Jade West Lake residential project comprises 20 small high-rise buildings, with a total roof area of 12,000 square meters. The roofing material

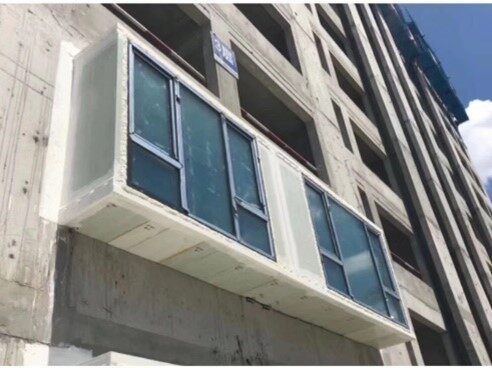

The FRP assembled floating windows produced by Changchun Parkview incorporate hollow web panels manufactured by Spare. The use of these panels allows for easy and

The connecting corridor in the Qingdao Golden Land Bay project is built with 800*300 large rectangular tubes produced by Spare using pultruded and formed profiles.