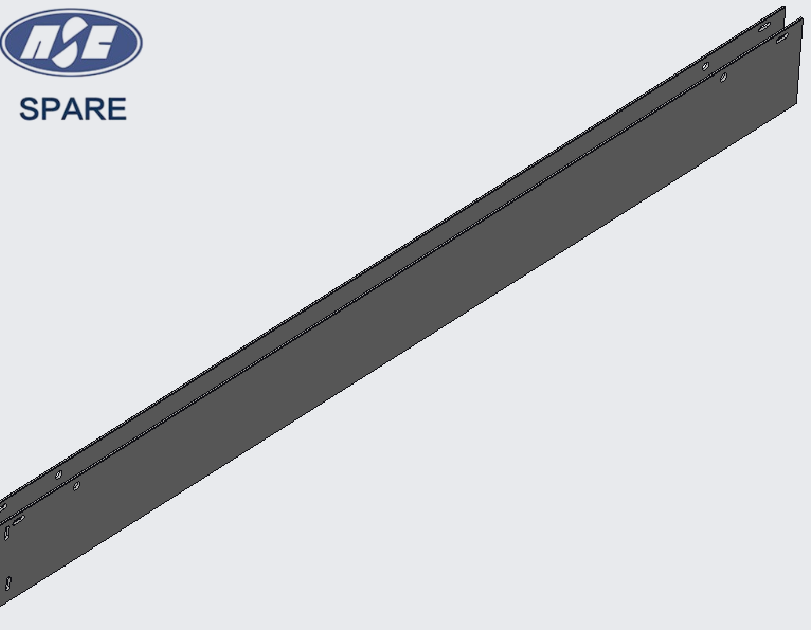

FRP pultruded grating is a sheet with gaps made by using pultruded I- and T-shaped profiles as load-bearing bars and solid pipes or rods as connecting penetration bars through a certain assembly process. FRP pultruded grating has a higher load-bearing capacity than FRP molded grating because it contains higher glass fiber reinforcement.

Pultruded grating has the strength of steel at a fraction of its weight and will not corrode. Grating panels are easy to transport and can be fabricated with standard hand tools.

•Corrosion resistant -Helps reduce maintenance and replacement costs

•Non-slip top surface -Increases workplace safety

•Strong and lightweight -Helps reduce installation costs

•Low coefficient of expansion and contraction -Dimensionally stable in many environments

Applications

•Flooring systems

• Sidewalks

• Work platforms

•Stairs

• Ramps

• Trench covers

• Overpasses

"*" indicates required fields

The apron, situated atop the Tres Cruces Hospital in Bilbao, Spain, spans 3 meters and can accommodate helicopters weighing up to 6 tons (13,200 lbs).

The connecting corridor in the Qingdao Golden Land Bay project is built with 800*300 large rectangular tubes produced by Spare using pultruded and formed profiles.

The corridor bridge connecting the old and new pavilions of Tsinghua University Civil Engineering Department was designed with Spare GFRP panels as permanent formwork for

The FRP cooling tower utilized in the Shanghai Laogang Renewable Energy Utilization Center Phase II Project was designed by SPX Company. It is a mechanical

The Rama 8 Bridge, situated over the Chao Phraya River in Bangkok, the capital of Thailand, was completed in 2001 and has since been operational.

The Chongqing Dongshuimen Bridge, completed in 2014, is a prominent landmark urban landscape and a vital public-rail dual-use bridge that spans the Yangtze River, linking