Pultruded fiberglass tubes are made of a composite material consisting of polyester resin and glass fibers that are lightweight and durable. The pultrusion process produces fiber reinforced plastic (FRP) with continuous lengths of reinforcing fibers, which gives fiberglass tubing exceptional tensile strength despite its light weight.

The pultrusion process also allows fiberglass tubing to be customized to almost any size and shape to meet a wide range of requirements. Standard shapes include round, square or rectangular profiles, which can be used as structural pultrusion or pultruded electrical shapes.

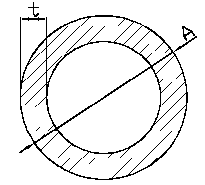

| round tube | S/N | A | t | Number | |

|

1 | 244.475 | 3.24 | G-0715 | |

| 2 | 193.675 | 3.24 | G-0713 | ||

| 3 | 168 | 6 | G-0506 | ||

| 4 | 155 | 6 | G-0505 | ||

| 5 | 152 | 4 | G-0529 | ||

| 6 | 130 | 6 | G-0504 | ||

| 7 | 123 | 6 | G-0503 | ||

| 8 | 117 | 6 | G-0502 | ||

| 106 | 3.5 | G-0126 | |||

| 9 | 104 | 6 | G-0501 | ||

| 10 | 98 | 6 | G-0500 | ||

| 11 | 92 | 8 | G-0517 | ||

| 12 | 92 | 6 | G-0499 | ||

| 13 | 85 | 6 | G-0498 | ||

| 14 | 82 | 3 | G-0587 | ||

| 15 | 79 | 6 | G-0497 | ||

| 16 | 76 | 6 | G-0124 | ||

| 17 | 76 | 4 | G-0125 | ||

| 18 | 73 | 5 | G-0123 | ||

| 19 | 71 | 3.5 | G-0122 | ||

| 20 | 60.33 | 4.7 | G-0462 | ||

| 21 | 60 | 3.5 | G-0121 | ||

| 22 | 60 | 2.63 | G-0146 | ||

| 23 | 51.6 | 2.55 | TX-0199 | ||

| 24 | 50 | 5 | G-0585 | ||

| 25 | 50 | 2.6 | G-0750 | ||

| 26 | 50 | 2.6 | G-0751 | ||

| 27 | 50 | 3.5 | G-0752 | ||

| 28 | 50 | 2.8 | G-0413 | ||

| 29 | 50 | 2 | G-0586 | ||

| 31 | 48.5 | 6.75 | G-0410 | ||

| 32 | 48.5 | 2.5 | G-0439 | ||

| 33 | 44 | 2.65 | G-0588 | ||

| 34 | 40 | 4 | |||

| 35 | 40 | 2 | G-0584 | ||

| 36 | 39.7 | 2.45 | G-0831 | ||

| ` | 39.7 | 3.2 | G-0340 | ||

| 37 | 38.35 | 4.83 | G-0680 | ||

| 38 | 38 | 5 | G-0120 | ||

| 39 | 38.1 | 4.7 | G-0522 | ||

| 40 | 38 | 2.45 | G-0620 | ||

| 41 | 38 | 3 | G-0132 | ||

| 42 | 36 | 5 | |||

| 43 | 36 | 2.2 | G-0460 | ||

| 44 | 36 | 3 | G-0311 | ||

| 45 | 32.14 | 3.5 | G-0764 | ||

| 46 | 31.5 | 3.18 | G-0315 | ||

| 47 | 31.5 | 2.54 | G-0315-2.5 | ||

| 48 | 31.5 | 2.25 | G-0469 | ||

| 49 | 32/34.5 | 3.25 | G-0138 | ||

| 50 | 32 | 4.8 | G-0119 | ||

| 51 | 32 | 3 | G-0130 | ||

| 52 | 32 | 2 | G-0117 | ||

| 53 | 32 | 2.5 | G-0118 | ||

| 54 | 30.3 | 2.5 | G-0375 | ||

| 55 | 30 | 4.8 | G-0131 | ||

| 56 | 30 | 2 | G-0116 | ||

| 57 | 30 | 2.5 | G-0342 | ||

| 58 | 28 | 3 | G-0115 | ||

| 59 | 28 | 4 | G-0128 | ||

| 60 | 28 | 2.75 | G-0423 | ||

| 61 | 28 | 1.5 | G-0422 | ||

| 62 | 27.4 | 3 | G-0136 | ||

| 63 | 26.97 | 2 | G-0379 | ||

| 64 | 26 | 2.5 | C-0465 | ||

| 65 | 25.4 | 3 | G-0137 | ||

| 66 | 25.4 | 2.5 | G-0114 | ||

| 67 | 25 | 3 | G-0354 | ||

| 68 | 25 | 2.5 | G-0354-2.5 | ||

| 69 | 25 | 2 | G-0139-2 | ||

| 70 | 24 | 2 | G-0135 | ||

| 71 | 24 | 3 | G-0113 | ||

| 72 | 23.8 | 1.99 | G-0135-2 | ||

| 73 | 23.5 | 3 | G-0135-3 | ||

| 74 | 23 | 3 | G-0112 | ||

| 75 | 23 | 2.5 | G-0129 | ||

| 76 | 22 | 2.5 | G-0134 | ||

| 77 | 22 | 3 | G-0425 | ||

| 78 | 22 | 1.5 | G-0424 | ||

| 79 | 21.5 | 2 | G-0145 | ||

| 80 | 20 | 2 | G-0111 | ||

| 81 | 19 | 3 | G-0110 | ||

| 82 | 18.8 | 3.2 | G-0133 | ||

| 83 | 12.7 | 1.75 | G-0226 | ||

The resin system and glass content can be adjusted during the manufacturing process to alter the composite matrix to produce pultruded fiberglass tubes with a variety of properties such as high strength, resistance to different temperature ranges, as well as flame retardant, track resistant and corrosion resistant properties.

Different colors can be achieved by adding pigments during the pultrusion process, and UV-resistant treatments can be added to increase the durability of the fiberglass in outdoor applications.

Advantages Of Pultruded Fiberglass Tubes & Pipes

Pultruded fiberglass tubes are superior to traditional materials such as wood, steel and aluminum in many ways. They are easier to handle, more durable, and produce safer products. Here are some of the key benefits of pultruded fiberglass tubing

Available in a variety of shapes, including round, square and rectangular, and in different sizes.

Provides high tensile strength, dimensional stability and stiffness.

Can be manufactured in any size and shape to meet a variety of design requirements.

30% lighter than aluminum and 70% lighter than steel without sacrificing any strength.

Resists deformation under high impact.

Can be cut and shaped with simple tools, so it is less costly and safer to work with.

An effective protective barrier for hot or electrically charged parts, as they do not conduct heat or electricity.

Non-magnetic electromagnetic transparency makes them ideal for professional and scientific applications.

Highly durable and chemically resistant.

Will not decay or degrade even after prolonged exposure to moisture, extreme temperatures or UV radiation.

Have a long life cycle (over 15 years) with very low maintenance costs because they do not deteriorate or rust.

Durability and recyclability provide sustainable solutions for the construction and manufacturing industries.

Provides the versatility needed in today’s manufacturing industry to create custom and complex designs to meet a variety of needs.

Pultruded Fiberglass Tubing Applications

Pultruded fiberglass tubing has unique properties for a wide range of applications.

Round tubes of various diameters are used for antenna enclosures, handles for tools (such as snow shovels, paint rollers, mops and brooms, lawn and garden tools), tree trimmers, professional service tools, railing systems, telescoping tools, and flagpoles.

Square and rectangular tubing is commonly used for insulators, railroad cross arms, spacers, frames, structural supports and bench slats.

Pultruded fiberglass tubing is widely used in many industries because of its low cost, light weight, ease of handling, versatility, strength, durability and long life cycle.

Construction and infrastructure: Commonly used for outdoor construction projects because they will not rot, rust, corrode or chip. They can be easily cut and shaped with simple tools, and low maintenance requirements often translate into a lower cost of ownership. They can be found in bridge components, corrosion-resistant guardrails, antenna enclosures, railroad crossing arms and highway sound barriers.

Utilities and telecommunications: Durable and non-conductive properties, along with non-magnetic electromagnetic transparency, make pultruded fiberglass tubing ideal for utility poles, cross arms and line markers, electrical wiring and raceways, wastewater and water treatment components, non-conductive elevator rails and fiber optic cabling.

Toolmaking. Because of its safety, versatility and reliability, fiberglass can be used to create ergonomic shapes for a variety of handheld tools or equipment. Because it is non-conductive, it is often used to protect the end user from high temperatures or energized components.

Sports, recreational and outdoor equipment: Pultruded fiberglass tubing is used for outdoor equipment that needs to withstand severe wear and tear. For example, outdoor furniture made of fiberglass can withstand prolonged exposure to moisture, sunlight and high temperatures.

Also, pultruded fiberglass tubing is often incorporated into sports equipment that needs to be lightweight, tough and reliable (e.g., golf clubs, field hockey sticks, sailing equipment, boat paddles, ski poles.)

"*" indicates required fields

The Beijing Vanke Jade West Lake residential project comprises 20 small high-rise buildings, with a total roof area of 12,000 square meters. The roofing material

The apron, situated atop the Tres Cruces Hospital in Bilbao, Spain, spans 3 meters and can accommodate helicopters weighing up to 6 tons (13,200 lbs).

Spare has developed and manufactured a significant component, the FRP connector, for sandwich wall construction. This connector is utilized to link the concrete slabs on

The corridor bridge connecting the old and new pavilions of Tsinghua University Civil Engineering Department was designed with Spare GFRP panels as permanent formwork for

The Rama 8 Bridge, situated over the Chao Phraya River in Bangkok, the capital of Thailand, was completed in 2001 and has since been operational.

The FRP cooling tower utilized in the Shanghai Laogang Renewable Energy Utilization Center Phase II Project was designed by SPX Company. It is a mechanical