With the rapid advancement of technology, the application of new materials has become increasingly widespread. Fiberglass profiles are one such exemplary representation. This innovative material, with its unique characteristics and advantages, has found extensive use in various contexts.

Fiberglass profiles are produced through pultrusion, using unsaturated polyester resin as the matrix, reinforced by glass fiber mat. They boast numerous exceptional qualities: including corrosion resistance, lightweight, high strength, aging resistance, easy installation, stable performance, and aesthetics, making them widely applied in diverse situations.

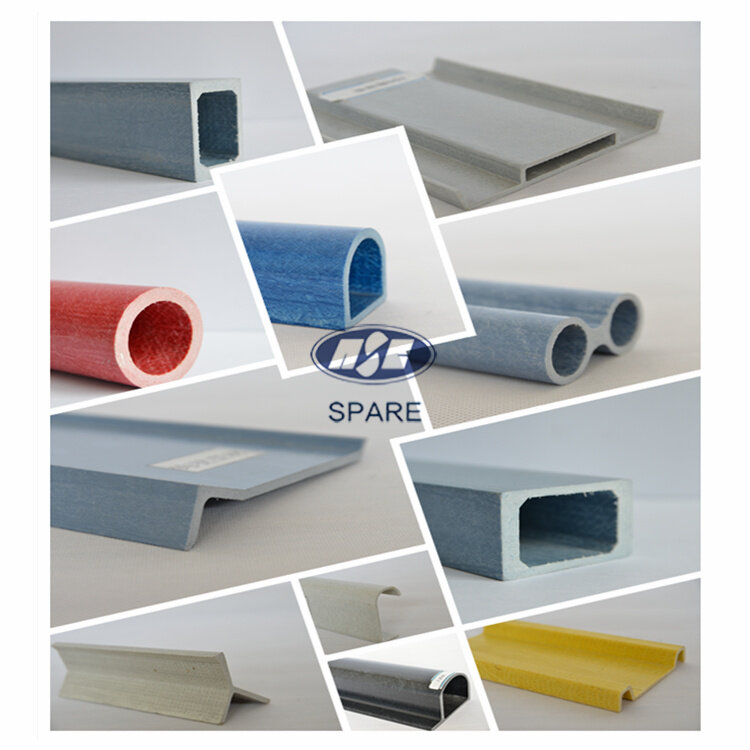

In terms of profile shapes, fiberglass materials come in various forms, such as round rods, pipes, angle steel, square tubes, channel steel, I-beams, T-beams, gratings, and special-shaped pieces. This rich array of shape options allows it to meet the needs of various usage scenarios.

For instance, in the field of building materials and home furnishings, its corrosion resistance and aging resistance characteristics make it a frequent choice for outdoor furniture or decorative materials. In areas like cooling towers, railings, operating platforms, municipal facilities, and chemical industries, its high strength, easy installation, and stable performance make it an ideal building material.

However, despite the numerous advantages of fiberglass profiles, we need to choose carefully according to specific requirements in practical use. First, we need to source from a reputable manufacturer to guarantee the quality and safety of the product, avoiding inferior materials masquerading as top-quality. Additionally, we need to choose the right resin according to the actual working conditions and usage environment. Different types of resins have varying degrees of corrosion resistance. If a high degree of corrosion resistance is required, vinyl ester resin should be chosen.

In conclusion, fiberglass profiles, with their unique performance and advantages, are widely used in various fields. Nevertheless, when selecting them for use, we should pay attention to the quality of the product and the choice of raw materials, so as to better utilize their performance and meet our requirements.