Introduction:

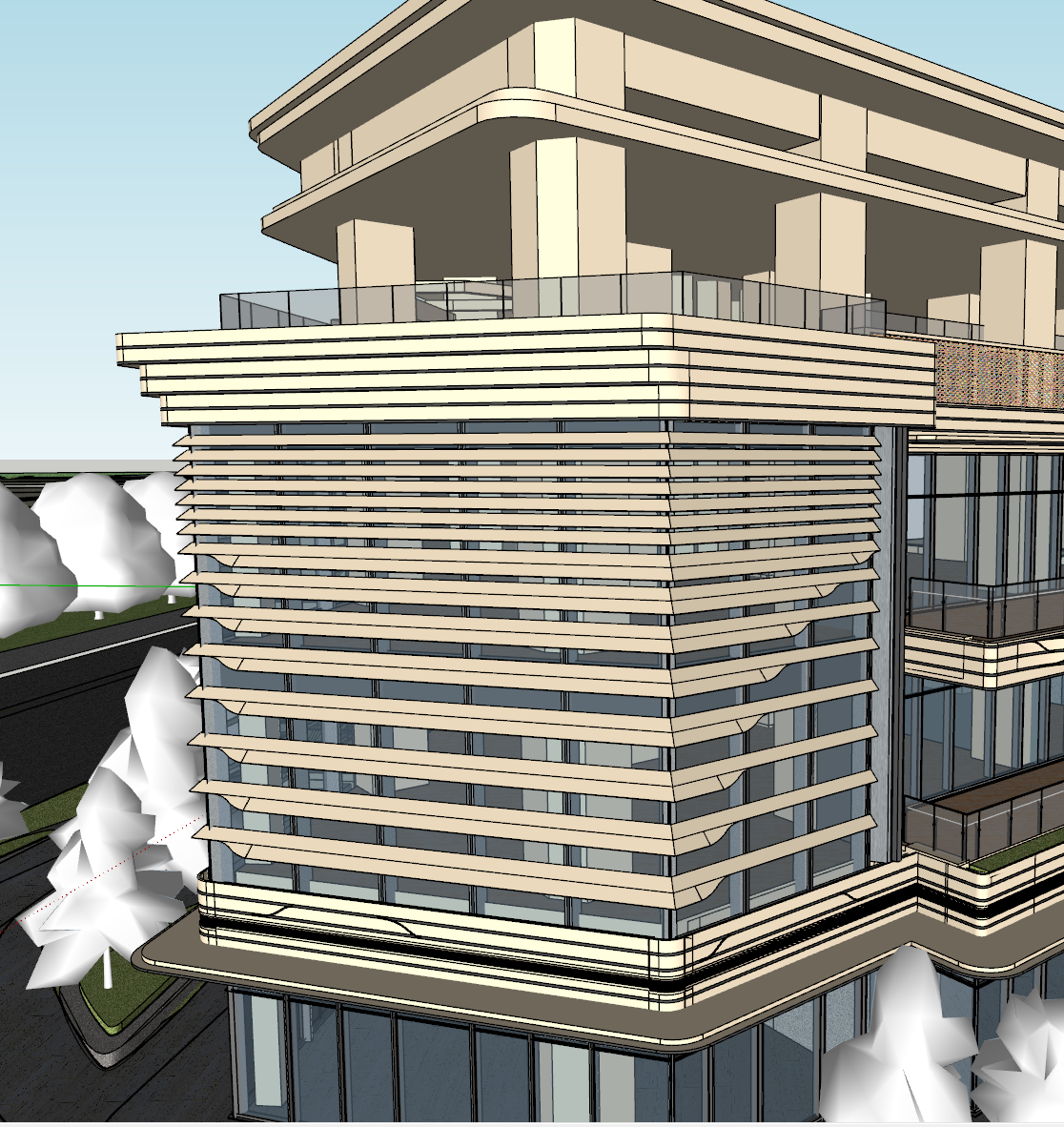

Coastal urban development poses unique challenges, especially in choosing construction materials that can withstand harsh marine environments. Louvers, critical for controlling light and air flow in buildings, have traditionally been made from metals; however, Fiber Reinforced Polymer (FRP) is making significant inroads in this application. This paper provides an in-depth technical analysis of FRP louvers, emphasizing their lightweight nature, ease of installation, and superior corrosion resistance compared to metal alternatives.

1. Unmatched Corrosion Resistance:

– Coastal cities are characterized by their saline-rich air, which can be detrimental to metal structures. Corrosion tests, such as the ASTM B117 salt spray test, have demonstrated that:

– Metals like steel and aluminum begin to exhibit signs of corrosion after just a few months of exposure.

– FRP, imbued with inherent corrosion-resistant properties, shows negligible signs of wear even after years in similar conditions.

This resistance translates into longer lifespan for FRP louvers and a significant reduction in maintenance and replacement costs.

2. A Featherweight Champion:

– Weight Analysis:

– FRP materials typically weigh approximately one-third of an equivalent aluminum structure and one-fifth of steel.

– The lightweight nature of FRP not only reduces the load on supporting structures but also decreases the energy and costs associated with transportation and handling during construction.

3. Ease of Installation:

– The installation process for FRP louvers is far more straightforward compared to heavy metal louvers. This ease is due to FRP’s lightweight characteristic, which often negates the need for heavy lifting equipment. Data from construction case studies indicate that:

– Installation time for FRP louvers can be up to 50% faster than that of metal louvers.

– This time efficiency can translate to a reduction in overall labor costs by a similar margin.

4. Durability in the Face of Adversity:

– Durability tests indicate that FRP’s tensile strength and flexural properties often exceed those of conventional metal louvers, especially after prolonged exposure to coastal conditions.

– The durability of FRP is attributed to its non-metallic nature, ensuring that the material does not weaken, delaminate, or degrade under conditions that would typically compromise metal.

5. Comparative Cost Analysis:

– While FRP may present a higher initial material cost compared to some metals, the total cost of ownership over the lifespan of the product is significantly lower. Cost analyses reveal that:

– The maintenance cost for metal louvers over a 10-year period can be as high as 15-20% of the initial cost due to corrosion-related issues.

– FRP louvers, in contrast, exhibit maintenance costs below 5%, owing to their inherent corrosion resistance.

6. Enhanced Construction Aesthetics:

– FRP louvers offer superior aesthetic versatility with a wide range of colors and finishes that remain consistent over time, resisting the fading and discoloration that are commonplace with metal in saline environments.

Conclusion:

The deployment of FRP in the construction of louvers for buildings in coastal cities presents an advantageous alternative to traditional metal options. The empirical data paints a clear picture: FRP louvers stand superior in their resistance to corrosive elements, ease of installation, and overall durability. These factors, coupled with long-term economic benefits and aesthetic adaptability, solidify FRP’s position as the material of choice for sustainable, resilient urban development in coastal regions. As the construction industry continues to innovate, FRP louvers are set to become a mainstay, redefining the standards of building materials in challenging environments.