On October 29-30,2020, China Household Electrical Appliances Technical Conference was officially held in Ningbo, Zhejiang province. As an important technology communicate platform of household appliances industry in China, the theme of this conference is “Wisdom, Green, Quality, Material”, focusing on the international home appliances technology development trend and common technology closely related to household appliances, highlight intelligent, digital, green, health, new technology, new application and the latest achievements of international and domestic materials, not only involve frontier trend but also cover practical technology.

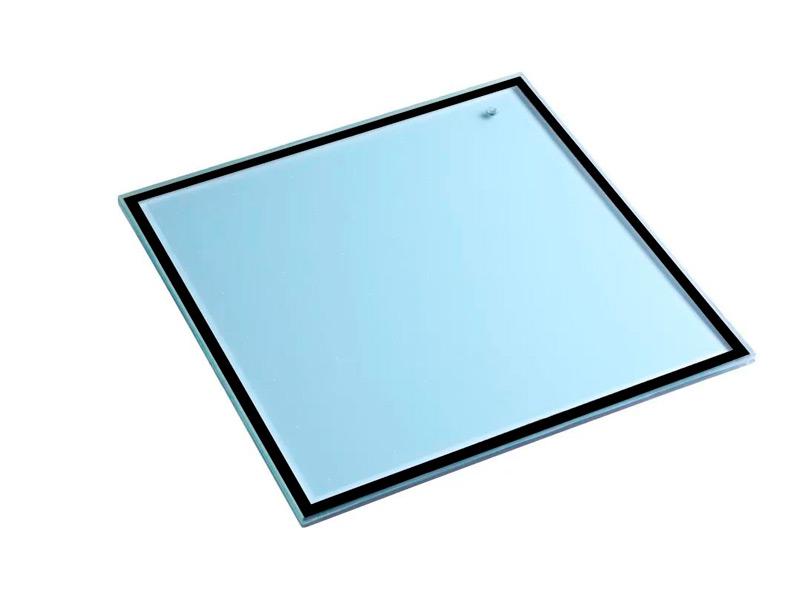

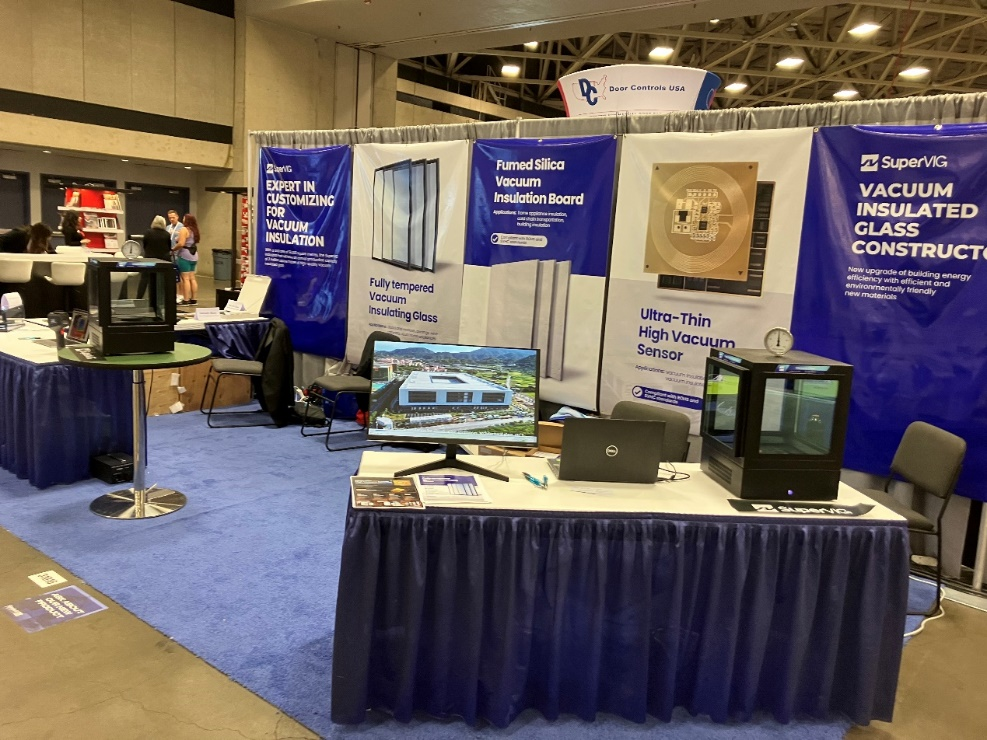

What worth paying attention is that at 2020 China Household Electrical Appliances Technical Conference, Supertech Advaned Material introduced it’s sub-brand — VIG. Adhering to the concept of green and healthy environmental protection, VIG focuses on the research and production of innovative vacuum insulating glass. The high-performance vacuum insulating glass will assist the electrical industry open a transparent, energy-saving and frost-free new world.

Different from the traditional vacuum insulating glass manufacturing process, VIG innovates the production process to complete the welding of two pieces of glass under high vacuum environment to ensure the ideal vacuum degree and make the appearance of the glass flat without air holes. In addition, VIG also independently developed alloy solder to realize wet welding under ultra-low temperature environment, which ensures the sealing quality of vacuum insulating glass. The vacuum leakage rate of the weld can be as low as 10-12 mbar. L/s, ensure the long service life of the product.

Thermal insulation

Experimental studies find that the radiation heat transfer of vacuum insulating glass is close to 5% of ordinary glass, the conduction heat transfer is about 0.001% of the total heat transfer area, and the gas convection and gas conduction are close to infinitesimal. The heat transfer coefficient U (K) value of vacuum insulating glass is about 0.5W/㎡·K. Compared with PU material of the same thickness, the U (K) value is 2.66W /㎡·K, so the comparison is clear at a glance.

Anti-frost

The test data show that vacuum insulating glass’s dew point temperature is much lower than -60℃, has strong frost resistance. This feature is reflected in the refrigerator products, which can make refrigerator and freezer being visible, and enrich the use experience of the public. The anti-frost performance has an outstanding advantage, especially for the northern cold areas. In winter, due to the sudden drop in temperature, the north would enter the season of glass freezing, with a thick layer of frost covering doors, windows, car glass, etc., causing inconvenience to people’s lives. The use of VIG’s vacuum insulating glass can perfectly solve the dilemma of glass freezing in northern winter.

Exclude noise

The high vacuum inner cavity of vacuum insulating glass effectively blocks the transmission of sound, and the weighted sound insulation volume exceeds 40 db, and its sound insulation effect is much better than that of hollow and ordinary glass. Especially for the traffic noise, construction noise and other strong penetration of medium and low frequency noise has a significant effect. To create a peaceful world for the public, vacuum insulating glass is the best choice.