With the development of technology, there is an increasing demand for energy, and solar energy, as a clean and renewable source, has attracted growing attention.

Photovoltaic panels, as one of the main devices for solar power generation, have had their efficiency and cost as key factors limiting their widespread application. In order to address these issues, scientists are continuously exploring new materials and technologies. Among them, engineering plastics, with excellent comprehensive properties such as high rigidity, low creep, high mechanical strength, good heat resistance, and excellent electrical insulation, have emerged as a crucial alternative to metals for structural materials in photovoltaic panel manufacturing.

According to data from market research institutions, the annual output value of the global photovoltaic component market is estimated to be around 4 to 5 billion US dollars, with over 50% of it being utilized for plastic components.

What are Engineering Plastics

Engineering plastics are a type of high-performance plastic known for their excellent mechanical properties, chemical resistance, thermal stability, and wear resistance. These plastics serve as engineering materials, capable of replacing metals in the manufacturing of machine components and other applications. They find widespread use in various industries, including electronics, automotive, construction, office equipment, machinery, aerospace, and more.

The development of engineering plastics not only supports key national industries and modern high-tech sectors but also stimulates the transformation of traditional industries and the adjustment of product structures. Their versatility makes them suitable for a wide range of complex engineering applications, providing innovative solutions across different sectors and playing a crucial role in modern manufacturing.

Application of Various Engineering Plastics in Photovoltaic Panels

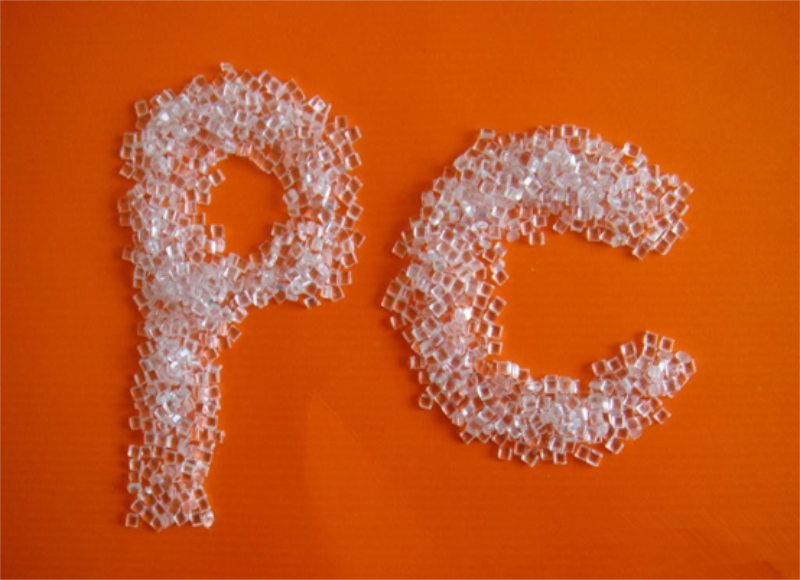

01 Polycarbonate (PC)

Polycarbonate is an optical plastic known for its high strength, impact resistance, and transparency. It is lighter than glass, possesses good weather resistance, and is resistant to chemical corrosion. Polycarbonate is commonly used in the manufacturing of protective eyewear, safety face shields, car lamp covers, display panels, etc.

Application of Polycarbonate in Photovoltaic Panels

(1) Enclosure Material: Polycarbonate, with its high strength, impact resistance, and transparency, is frequently used as the enclosure material for photovoltaic panels. It serves to protect solar cells and other crucial components from external environmental damage such as impacts, weather, and UV radiation.

(2) Backsheet Material: In photovoltaic panels, polycarbonate can also function as the backsheet material. The backsheet is located on the backside of solar cells, providing structural support and protection for the battery components. Polycarbonate backsheets offer good strength and weather resistance, effectively safeguarding solar cells and extending their lifespan.

(3) Sealing Material: Photovoltaic panels require excellent sealing performance to prevent moisture, dust, and other contaminants from entering the panel’s interior. Polycarbonate can be used as a sealing material to encapsulate and secure solar cells and other components, ensuring the long-term stable operation of photovoltaic panels.

(4) Optical Waveguide Plate: Polycarbonate materials have high light transmission performance, making them suitable for manufacturing optical waveguide plates. Optical waveguide plates are used to guide light from the edges of the photovoltaic panel to the solar cell area, enhancing the efficiency of light utilization.

Key Suppliers

Bayer AG, LG Chem, Sumitomo Chemical Co., Ltd., Mitsubishi Chemical Corporation, Sumitomo Chemical Co., Ltd., Japan Electrical Chemicals (NEC), Shanghai Organic Glass Factory Co., Ltd.

Advantages of Polycarbonate

(1) Impact Resistance: Polycarbonate exhibits excellent impact resistance, effectively preventing panel breakage or damage.

(2) High Transparency: Polycarbonate has excellent transparency, efficiently transmitting sunlight to the solar cell layer.

(3) Lightweight: Compared to traditional glass materials, polycarbonate is lighter, contributing to the reduction of the weight of photovoltaic panels, facilitating installation and transportation.

(4) Weather Resistance: Polycarbonate has good weather resistance, resisting the impact of UV radiation, humidity, and temperature changes, maintaining the stability and durability of the panel.

In summary, polycarbonate is widely used in photovoltaic panels, providing critical functions such as protection, support, sealing, and optical transmission, contributing to the improvement of the performance and reliability of photovoltaic panels.

02 Polymethyl Methacrylate (PMMA)

Polymethyl methacrylate, also known as acrylic or acrylic glass, is an optical plastic characterized by excellent transparency and optical quality. It has high resistance to ultraviolet (UV) radiation and outstanding weather resistance.

Application of Polymethyl Methacrylate in Photovoltaic Panels

(1) Optical Lenses: PMMA, with its good transparency and optical quality, is commonly used in the manufacturing of optical lenses for photovoltaic panels. Optical lenses concentrate light onto the surface of solar cells, enhancing light absorption efficiency. PMMA lenses have a high transmittance, enabling more effective conversion of sunlight into electricity.

(2) Optical Waveguide Plates: Optical waveguide plates guide light from the edges of photovoltaic panels to the solar cell area, improving light utilization efficiency. PMMA, with its high light transmission performance, can be used to manufacture optical waveguide plates, optimizing light distribution and transmission to enhance panel efficiency.

(3) Protective Covers and Enclosures: PMMA can also serve as protective covers and enclosure materials for photovoltaic panels. It possesses excellent transparency and impact resistance, effectively protecting solar cells and other crucial components from external environmental damage, such as impacts, weather, and UV radiation.

Key Suppliers

Evonik Industries, Rohm Co., Ltd., Mitsubishi Chemical Corporation, Sumitomo Chemical Co., Ltd., Chimei Corporation, KOLON Industries, Inc., Kuraray Co., Ltd., Suzhou Double Elephant Microfibers Co., Ltd., Wanhua Chemical Group Co., Ltd., Huizhou Huifeng Chemical Co., Ltd.

Advantages of Polymethyl Methacrylate

(1) High Transparency: PMMA has excellent transparency, efficiently transmitting sunlight to the solar cell layer, thereby enhancing light absorption efficiency.

(2) Lightweight: PMMA has a low density, making it a material that can reduce the overall weight of photovoltaic panels, facilitating installation and transportation.

(3) Weather Resistance: PMMA exhibits good weather resistance, resisting the impact of UV radiation, humidity, and temperature changes, extending the panel’s lifespan.

(4) Impact Resistance: PMMA has good impact resistance, effectively protecting solar cells and other key components from external impacts.

In summary, PMMA, used as optical lenses, optical waveguide plates, and enclosure materials for photovoltaic panels, offers excellent transparency, lightweight properties, weather resistance, and impact resistance. It plays a crucial role in improving light absorption efficiency, light distribution and transmission, and protecting solar cells in photovoltaic panels.

03 Polystyrene (PS)

Polystyrene is an optical plastic with high transparency and refractive index. It exhibits good optical uniformity and surface quality, commonly used in the manufacturing of optical lenses, substrates, and optical waveguides.

Application of Polystyrene in Photovoltaic Panels

(1) Dielectric Layer: The dielectric layer in photovoltaic panels is positioned between the solar cells and the backsheet, serving to isolate the current between cells and other components, preventing short circuits and damage. Polystyrene film can be used as a dielectric layer material, providing insulation properties that effectively isolate the current.

(2) Optical Waveguide Plate: Optical waveguide plates in photovoltaic panels guide light from the panel’s edges to the solar cell area, enhancing light utilization efficiency. Polystyrene, with its high light transmission performance, can be utilized as a material for optical waveguide plates, assisting in optimizing light distribution and transmission.

(3) Auxiliary Components: Polystyrene can also be employed for auxiliary components in photovoltaic panels, such as support structures and connectors. Due to its low density and good processing characteristics, polystyrene can offer lightweight support and connection solutions.

Key Suppliers

DOW (Dow Chemical), BASF, FINA, CHEVRON (Chevron Phillips Chemical Company), INEOS Styrolution, TotalEnergies, Styron (Trinseo), Sinopec, JSP (Jiangsu Sunplas Co., Ltd.).

Advantages of Polystyrene

(1) Low Cost: Polystyrene is a common plastic with lower manufacturing costs, contributing to the reduction of production costs for photovoltaic panels.

(2) Lightweight: Polystyrene has a low density, making it relatively lightweight, facilitating the reduction of the overall weight of photovoltaic panels for easier installation and transportation.

(3) Insulation Performance: Polystyrene exhibits good insulation properties, effectively isolating the current and improving the safety and reliability of photovoltaic panels.

(4) Light Transmission Performance: Polystyrene has high transparency and light transmission performance, aiding in the more effective transmission of light to the solar cell layer, thus enhancing the light absorption efficiency of photovoltaic panels.

04 Polyethylene (PE)

Polyethylene is a common plastic material known for its high transparency and excellent chemical corrosion resistance. It is typically used in the manufacturing of films, packaging materials, optical coatings, etc.

Application of Polyethylene in Photovoltaic Panels

(1) Backsheet Material: Polyethylene can be used as the backsheet material for photovoltaic panels. The backsheet is located on the backside of solar cells, providing structural support and protection for the battery components. Polyethylene backsheets exhibit good strength, weather resistance, and chemical corrosion resistance, effectively safeguarding solar cells and extending their lifespan.

(2) Sealing Material: Photovoltaic panels require effective sealing to prevent moisture, dust, and other contaminants from entering the panel’s interior. Polyethylene can be utilized as a sealing material for encapsulating and securing solar cells and other components, ensuring the long-term stable operation of photovoltaic panels.

(3) Auxiliary Components: Polyethylene can also be used for auxiliary components in photovoltaic panels, such as support structures and connectors. Due to its low density and good processing characteristics, polyethylene can provide lightweight support and connection solutions.

Key Suppliers

Toray Industries, Inc., LG Chem, Sumitomo Chemical Co., Ltd., Mitsubishi Chemical Corporation, Japan Electrical Chemicals (NEC), Shanghai Organic Glass Factory Co., Ltd.

Advantages of Polyethylene as Photovoltaic Panel Material

(1) Low Cost: Polyethylene is a common plastic with lower manufacturing costs, contributing to the reduction of production costs for photovoltaic panels.

(2) Lightweight: Polyethylene has a low density, making it relatively lightweight, facilitating the reduction of the overall weight of photovoltaic panels for easier installation and transportation.

(3) Weather Resistance: Polyethylene exhibits good weather resistance, resisting the impact of UV radiation, humidity, and temperature changes, extending the panel’s lifespan.

(4) Chemical Corrosion Resistance: Polyethylene has good chemical corrosion resistance, with the ability to resist some chemicals, enhancing the durability of photovoltaic panels.

05 Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene is an optical plastic known for its inert nature and high temperature resistance. It exhibits excellent chemical resistance, heat resistance, and a low friction coefficient, commonly used in the manufacturing of optical coatings, sealing materials, and optical devices in high-temperature environments.

Application of Polytetrafluoroethylene in Photovoltaic Panels

(1) Dielectric Layer: Polytetrafluoroethylene can be used as one of the dielectric layer materials in photovoltaic panels. The dielectric layer is positioned between the solar cells and the backsheet, isolating the current between cells and other components to prevent short circuits and damage. PTFE has excellent insulation properties and chemical corrosion resistance, effectively isolating the current.

(2) Sealing Material: Photovoltaic panels require effective sealing to prevent moisture, dust, and other contaminants from entering the panel’s interior. PTFE, with outstanding chemical corrosion resistance, high-temperature resistance, and a low friction coefficient, can serve as an excellent sealing material, ensuring the long-term stable operation of photovoltaic panels.

(3) Coating Material: PTFE can be used as a coating material for photovoltaic panels, providing functions such as anti-soiling, scratch resistance, UV resistance, and weather resistance. It possesses good chemical resistance and low surface adhesion, allowing the coating to protect the panel surface from contamination and damage.

Key Suppliers

DuPont, LG Chem, Toray Industries, Inc., Sumitomo Chemical Co., Ltd., Mitsubishi Chemical Corporation, Japan Electrical Chemicals (NEC), Shanghai Organic Glass Factory Co., Ltd.

Advantages of Polytetrafluoroethylene as Photovoltaic Panel Material

(1) High Temperature Resistance: PTFE has excellent high-temperature resistance, maintaining stability in high-temperature environments suitable for the working conditions of photovoltaic panels.

(2) Chemical Corrosion Resistance: PTFE exhibits outstanding chemical corrosion resistance, resisting the corrosion of acids, alkalis, and other chemicals, thereby extending the panel’s lifespan.

(3) Low Friction Coefficient: PTFE has an extremely low friction coefficient, reducing surface friction and wear, enhancing the performance and lifespan of the panel.

(4) Excellent Anti-soiling Performance: PTFE coatings demonstrate excellent anti-soiling performance, effectively reducing the adhesion of dirt and dust, maintaining the cleanliness and light absorption efficiency of the panel. It’s important to note that the manufacturing and application of PTFE require special handling and technical requirements due to its poor adhesion to other materials. Therefore, when using PTFE in photovoltaic panels, appropriate processing and bonding methods are necessary to ensure good adhesion and collaboration with other components.

Development Prospects and Challenges of Engineering Plastics

Prospects

Lightweight and Flexibility

Engineering plastics exhibit characteristics of lightweight and flexibility, making them suitable for applications in flexible photovoltaic technology and bendable batteries. This facilitates the realization of more flexible and lightweight photovoltaic devices in various scenarios.

Lower Production Costs

Utilizing engineering plastics for photovoltaic materials generally incurs lower manufacturing costs compared to traditional glass materials. This helps reduce the production costs of photovoltaic panels, enhancing the commercial competitiveness of photovoltaic technology.

Impact Resistance and Weatherability

Engineering plastics boast good impact resistance and weatherability, providing protection for solar cells and other components in harsh environmental conditions. This enhances the durability of photovoltaic panels, enabling them to operate stably outdoors over the long term.

Issues and Challenges

Engineering Performance

Photovoltaic panels require excellent optical performance, including factors such as transmittance, refractive index, and dispersion. When developing engineering plastic materials, it is crucial to ensure they can offer sufficient light transmission and transparency to maintain the efficiency of photovoltaic panels.

Thermal Stability

Photovoltaic panels operate in high-temperature environments, necessitating engineering plastics with good thermal stability to prevent softening or degradation of the plastic materials, which could impact the panel’s performance and lifespan.

UV Radiation Resistance

Photovoltaic panels need to withstand the impact of UV radiation to prevent aging and yellowing of plastic materials. Developing engineering plastics with good weather resistance and UV resistance poses a critical challenge.

Sustainability

In the field of photovoltaics, sustainability and environmental consciousness are becoming increasingly important. Developing recyclable and reusable engineering plastics and adopting environmentally friendly manufacturing and disposal methods are crucial aspects for driving sustainable development in the photovoltaic sector.

Currently, the application of engineering plastics in the field of photovoltaics is relatively new and is still in the research and development stage. Despite existing challenges, with technological advancements and innovations, the prospects for the application of engineering plastics in the photovoltaic field remain promising, holding the potential to bring more advantages and innovations to photovoltaic technology.