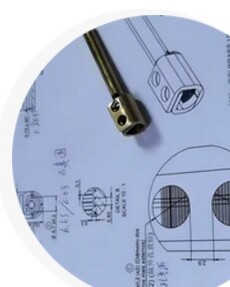

Founded in 2003 by entrepreneur Mr Lin, starting a small factory, we were focusing on turning and milling services.

Over the next decade, we introduced quick-turn CNC machining and expanded our capabilities in injection molding services.

In 2019, we launched 3D printing services with the cooperation of our partners to simplify the transition from early prototyping to low-volume production.

Acquiring a stamping factory in 2021 brought sheet metal fabrication into our suite of manufacturing services, further expanding our machining abilities.

Our 20 years of growth and expanding capabilities provide customers with the best on-demand parts experience in a variety of industries, from prototyping, low-volume production to high-volume manufacturing. This continued evolution shapes our vision and mission as a company.

Streamlined Solutions for Faster and More Cost-Effective Manufacturing.

Revolutionize the manufacturing landscape by providing scalable solutions to support various sectors.

Integrity, Innovation, and Customer Focus

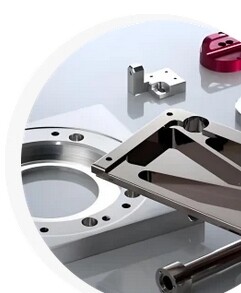

XuFeng is a provider of on-demand metal and plastic parts in China, leveraging over 20 years of machining expertise to produce top-quality components at competitive prices.

Our advanced manufacturing capabilities, including CNC machining, injection molding, sheet metal fabrication, and 3D printing, enable us to serve a broad range of industries with exceptional precision and efficiency.

As a comprehensive one-stop solution for manufacturing needs, XuFeng offers everything from prototyping to high-volume production. Our skilled engineers and cutting-edge facilities ensure a seamless transition from concept to final product, delivering significant savings in time, effort, and resources for our clients.

Xu Feng help you accelerate product development, reduce costs, and optimize your supply chain.

Over a decade in the machining industry gives us deep insight into your needs. This enables us to truly understand what you want and need, and to serve you in a way that helps you expand your business.

Quotes within hours, parts within days. Short manufacturing turnaround times support multiple design iterations.

Development is accelerated and products are launched to market faster than before

DFM analysis proceeds in every machining and molding quote, highlighting potential issues and providing immediate solutions. Prototype before mass production prevents costly investment mistakes.

Whatever metal and plastic component requirements, Xu Feng has you covered! With our own factories and reliable partners network, we offer seamless one-stop service for you.

Here are the resources Xu Feng provides to help you manage demand throughout the product life cycle.