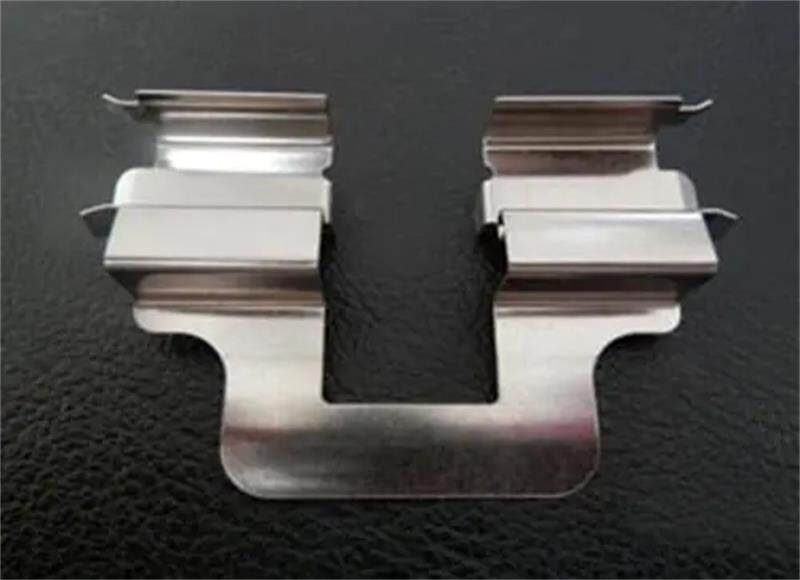

Metal stamping is a manufacturing process that involves forming a piece of sheet metal into a desired shape or configuration using a stamping press and dies. The process is commonly used to create various metal components and parts for a wide range of industries, including automotive, aerospace, electronics, appliances, and more.

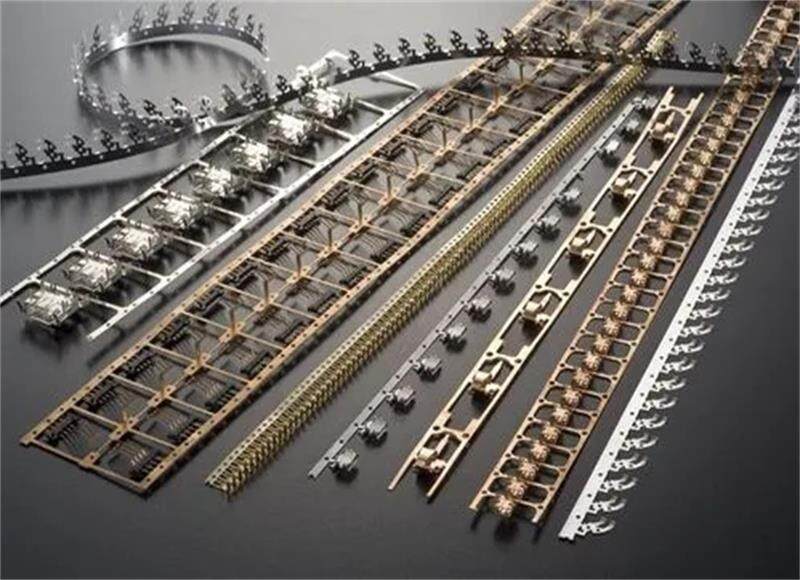

Xu Feng manufactures custom metal stampings in various materials, including copper, brass, stainless steel, and steel alloys. We offer service from stamping dies to large-volume parts production.

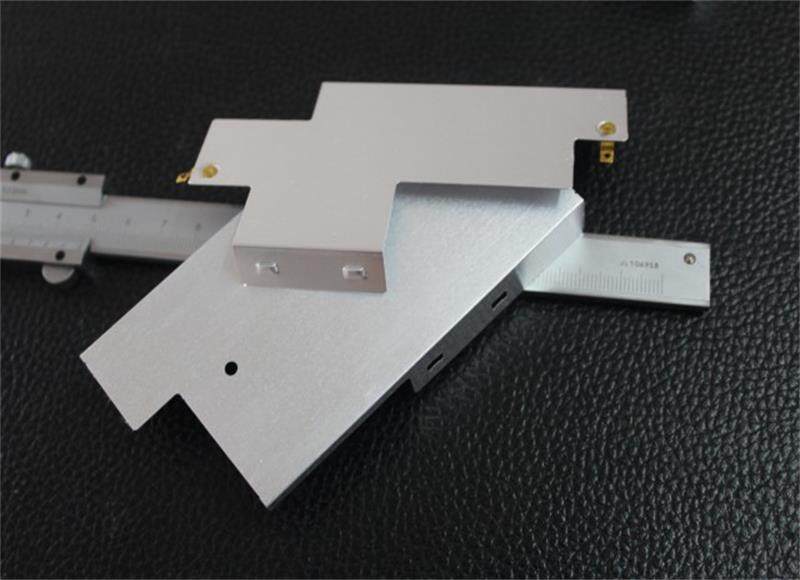

Our selection of materials for metal stamping includes copper, brass, steel, aluminum, and nickel for both our standard and custom requirements. The stamped material can undergo post-processing techniques such as bead blasting, powder coating, chemical film application, anodizing, and plating in gold, silver, electroless nickel, and various other surface treatments.

Often used in electrical components and decorative applications

Frequently used for decorative items and fittings

Used in various industries, including automotive, appliance, and aerospace etc.

Widely employed in automotive, aerospace, and electronics for its versatility

Used in applications requiring these specific properties

Depending on the specific requirements of the application, various specialty alloys may be utilized, Xu Feng can stamp other sheet metal materials on request, so feel free to contact our experts about the materials you need.

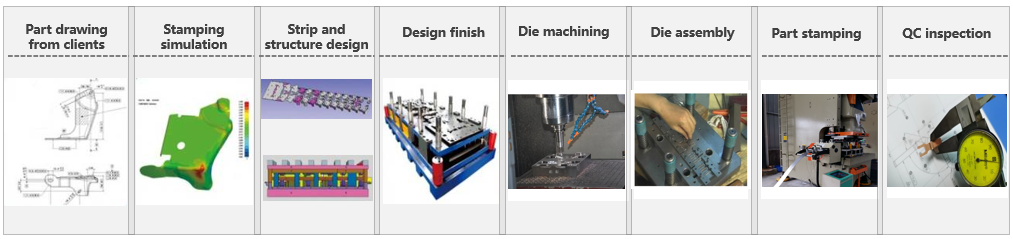

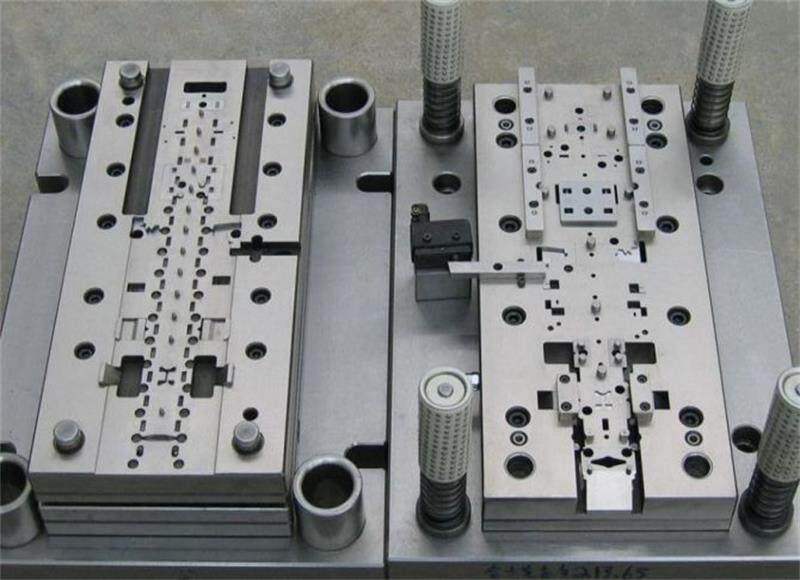

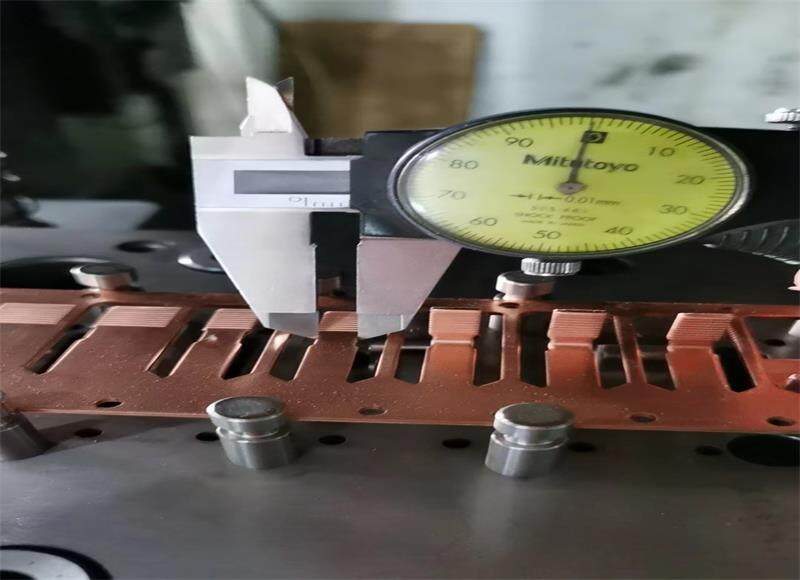

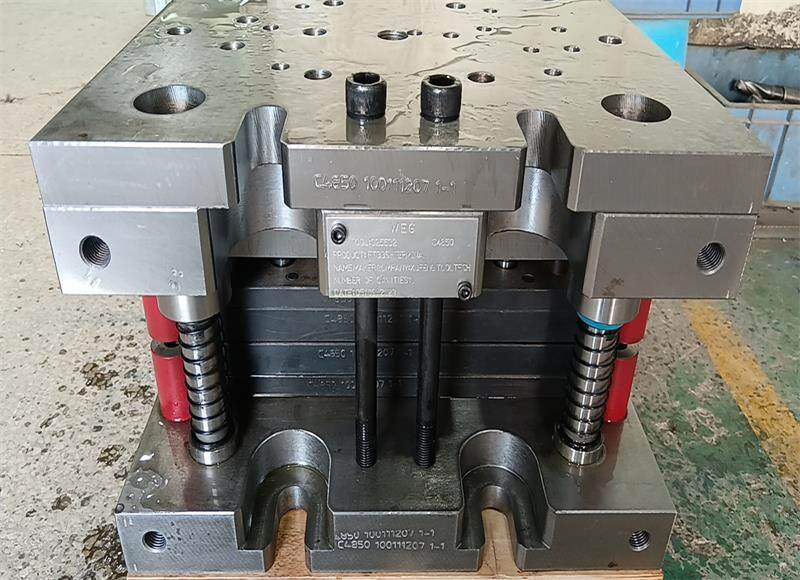

See how Xu Feng processes your orders, from quotation, high-quality stamping die making, to production high volume metal parts, ensuring timely delivery with our skilled team and machinery.