Rapid tooling refers to the process of quickly manufacturing tooling, such as molds or dies, to produce prototypes parts or low to moderate production volumes. The primary goal of rapid tooling is to reduce the time and cost associated with traditional tooling methods, allowing for faster iteration in product development or quicker respondse to market demands.

Product Development: Rapid tooling is integral in the early stages of product development, allowing designers and engineers to quickly test and refine designs.

Bridge to Production: It serves as a bridge between prototyping and full-scale production, enabling the production of limited quantities of parts without the need for expensive, high-volume tooling.

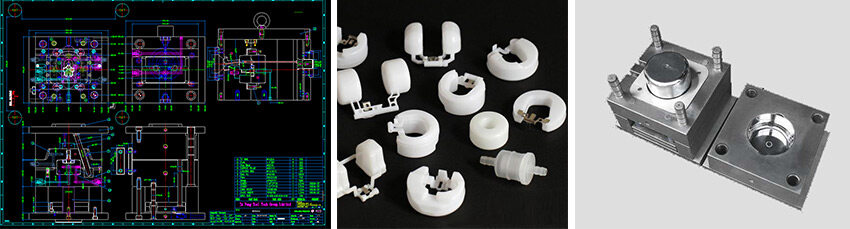

At Xu Feng, we can provide the rapid tooling include

Aluminum mold

Aluminum is chosen for its excellent machinablility, relatively low cost and good thermal conductivity, these properties make it well suited for rapid mold. It strikes a balance between speed, cost-effectiveness and durability, making it a valuable tool in prototyping and low-volume production.

Recommend material for aluminum mold

7075 Aluminum: the best material for aluminum mold, it has high strength and hardness, make it suitable for high-stress applications, such as injection molds for moderate volume production.

6061 Aluminum: Often used for molds where moderate strenth and good corrosion resistance are required, it’s suitable for low to moderate production volumes.

2024 Aluminum: Suitable for molds where high strength is a primary consideration.

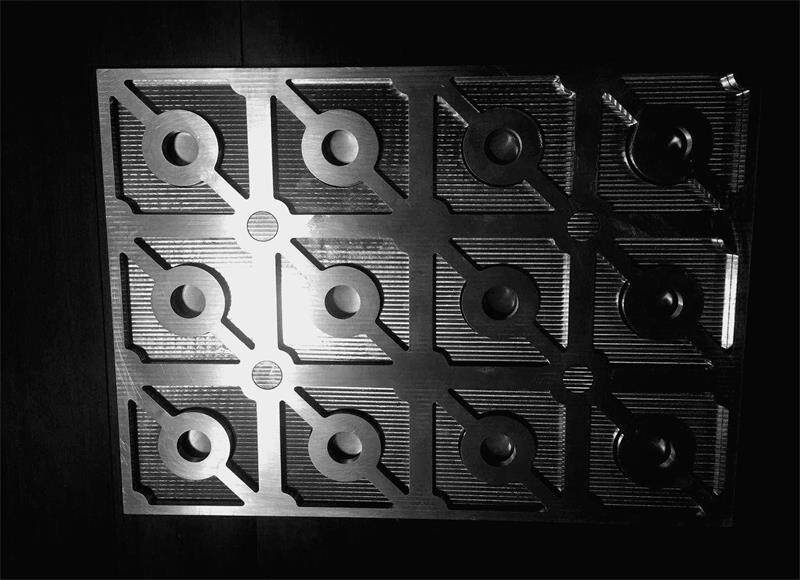

Soft mold

Soft mold typically refers to a mold made from materials that are more flexible or less rigid than traditional steel. Soft mold is used for prototyping or small productin runs. Production runs using soft mold typically produce about hundreds pieces of parts.

Recommend material for soft mold

Silicone Rubber: Silicone is a common material for soft molds due to its flexibility, high tear strength, and ability to capture intricate details.

Polyurethane (PU): Polyurethane materials can be used to create soft molds, offering flexibility and ease of handling.

Latex: Latex is another flexible material used for making molds, particularly in applications where cost-effectiveness is crucial.

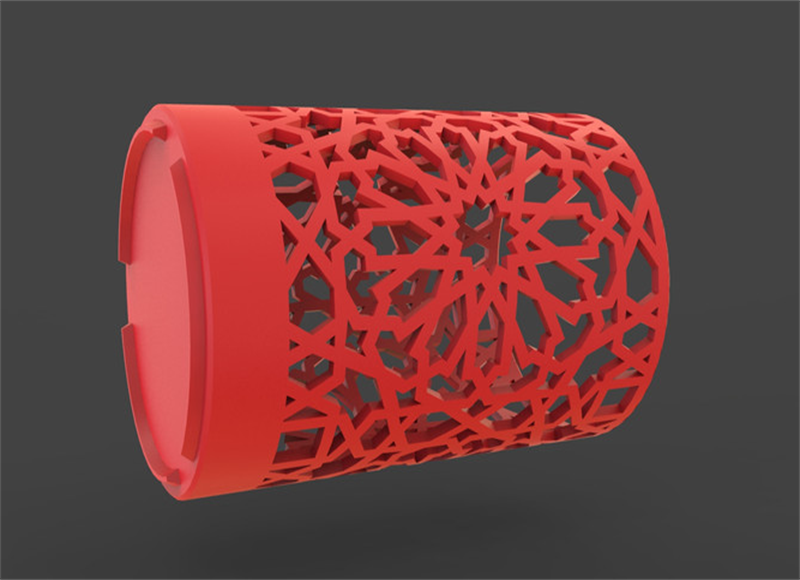

3D print

Rapid prototyping with 3D print enable you to print prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster.

Recommend material for 3D print

Nylon: Used for casings, housings, consumer sports equipment, intricate prototype plastic parts, and prototypes with specific shapes, assemblies, or functionalities.

Photosensitive Resin: Applied in the fields of household appliances, rapid manufacturing, prototype modeling, electronic products, educational research, architectural models, art models, and automotive manufacturing.

Wax (Red Wax): Widely employed in the creation of figurines, animations, exquisite artworks, and jewelry exhibits.