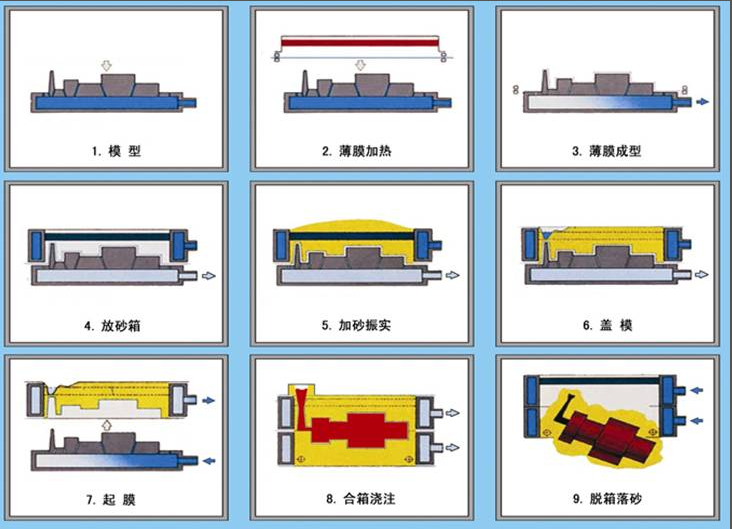

V-process casting and lost foam casting adopt Vacuum forming, but there are big differences in production technic. Vacuum process casting is named after the first letter “V” of the English word vacuum. V-process casting is different from the traditional sand casting, doesn’t use adhesive during production. V method casting is the use of plastic film sealed sand box, extracts the air inside of the mold by the vacuum pumping system, dry sand model becomes firmer through the pressure difference inside and outside of cast model, then get the required cavity. After putting core, pattern assembling, cast pouring, relieve the negative pressure, the required raw cast formed after sand model breaking.

The advantage of V-process casting compared with lost foam casting:

l As casting process by adopting the negative pressure, few sand holes and air holes, improving the density and surface texture of the raw casting, complete cast profile and accurate raw dimensions.

l Energy saving, high efficiency and clean production.

V-method casting is suitable for the production of castings in a wide range of materials, including but not limited to cast iron, cast steel, ductile cast iron, malleable cast iron, aluminum alloys, magnesium alloys, Copper alloys, heat and corrosion resistant alloys, etc. This casting method has a wide range of applications and is particularly suited to the production of small mass and thin-walled castings. One of the advantages of V-method casting is that it has a wide range of applications and can produce castings in a wide variety of materials, which makes it highly applicable in industrial production. In addition, V-method casting can also produce medium-sized castings with simple and more precise shapes, further proving its advantages in the production of specific types of products.