Precision casting, also known as investment casting, requires careful pattern creation to ensure high-quality final products. Here are the key matters needing attention during pattern creation:

- Material Selection for Patterns

Wax Patterns: Commonly used due to ease of molding and removal.

Polystyrene or 3D-Printed Patterns: Used for complex geometries.

Metal or Plastic Patterns: For high-volume production with reusable molds.

Thermal Expansion Consideration: Material should have minimal shrinkage to avoid dimensional inaccuracies.

- Dimensional Accuracy & Tolerances

Account for shrinkage allowance (metal contraction during cooling).

Apply machining allowance if post-casting finishing is required.

Ensure tight tolerances (±0.1–0.5% depending on material and size).

- Pattern Design Considerations

Draft Angles: Small angles (1–3°) to facilitate pattern removal from the mold.

Uniform Wall Thickness: Avoid sudden changes to prevent defects like shrinkage cavities.

Fillets & Radii: Sharp corners should be rounded to reduce stress concentrations.

Avoid Undercuts: Unless using soluble or collapsible cores.

- Gating & Feeding System Design

Sprue, Runners, and Gates: Properly sized to ensure smooth metal flow.

Risers (Feeders): Positioned to compensate for shrinkage during solidification.

Venting: Ensure gas escape paths to prevent porosity.

- Surface Finish & Detail Reproduction

High-quality surface finish reduces post-casting machining.

Fine details should be accurately replicated (critical for aerospace/medical parts).

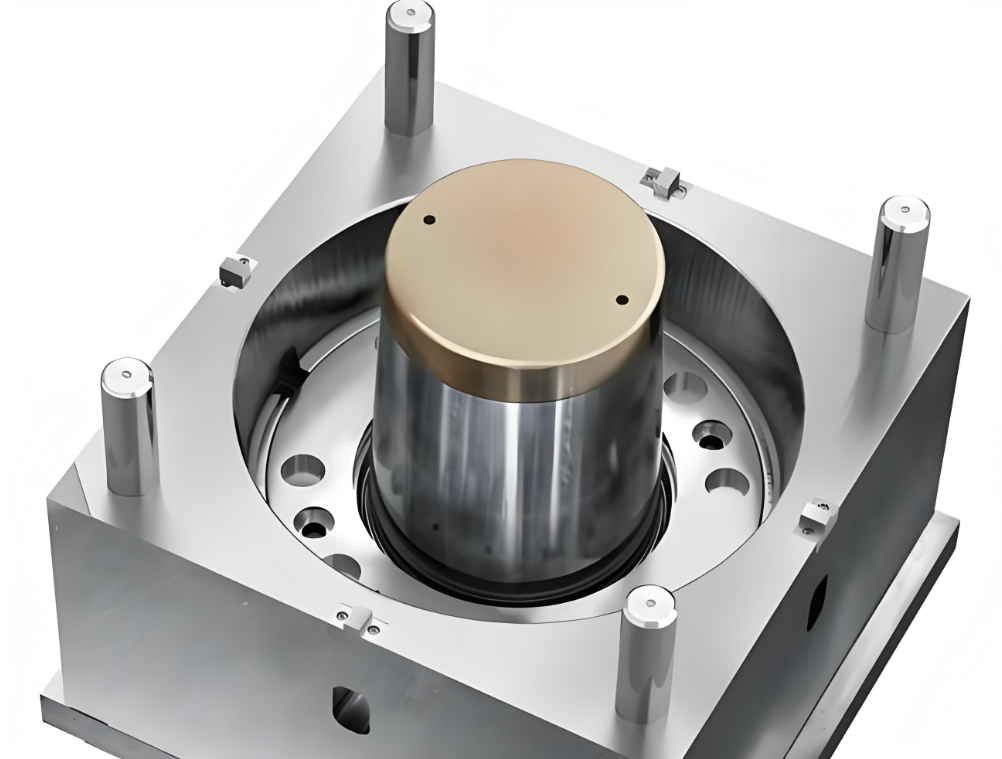

- Mold Compatibility

Patterns must align with investment material (ceramic shell or plaster mold).

Avoid reactions between pattern material and mold slurry.

- Pattern Assembly (for Wax Patterns)

Cluster Design: Multiple patterns can be joined to a central sprue for efficiency.

Wax Welding: Ensure strong joints to prevent breakage during handling.

- Temperature & Handling Control

Wax Patterns: Store in a temperature-controlled environment to prevent deformation.

3D-Printed Patterns: Post-curing may be needed for stability.

- Quality Inspection Before Casting

Dimensional Verification: Use CMM (Coordinate Measuring Machine) or optical scanners.

Visual Inspection: Check for cracks, distortions, or surface defects.

Trial Casting: Test runs to validate mold and pattern design.

- Environmental & Process Factors

Humidity Control: Affects wax and investment mold stability.

Pattern Removal Technique: Melt-out, burnout, or dissolution must leave minimal residue.

Precision in pattern creation directly impacts casting quality. Proper material selection, dimensional control, gating design, and inspection are critical to avoid defects like misruns, porosity, or dimensional inaccuracies in the final product.