Iron is undoubtedly one of the most commonly used materials worldwide. Ductile iron and cast iron are two of the most common types. They have numerous applications across different industries. We will discuss Ductile Iron VS Cast Iron.

What is Cast Iron?

Did you know that carbon and silicon are mixed with iron to form cast iron? When iron is melted, carbon and silicon are mixed in, resulting in cast iron. Furthermore, the grey color of the iron is due to the presence of graphite flakes.

It possesses excellent compressive strength and damping capacity. Where is cast iron used? You will find it in decorative items, pots and pans, piping, etc.

Properties

The main advantage of this cast iron is its durability. Castability is also one of the key advantages and is frequently utilized. Additionally, cast iron is the preferred choice considering its economy.

Disadvantages

However, it has one disadvantage: brittleness. Cast iron is sometimes prone to cracking, making it unsuitable for use in tensile stress areas.

What is Ductile Iron?

Ductile iron is known by different names, such as nodular cast iron and spheroidal graphite iron. Furthermore, it was a major invention in the mid-20th century. Why is it so popular? How does it differ from other types? Due to its microstructure, it offers unique flexibility, ductility, and even strength.

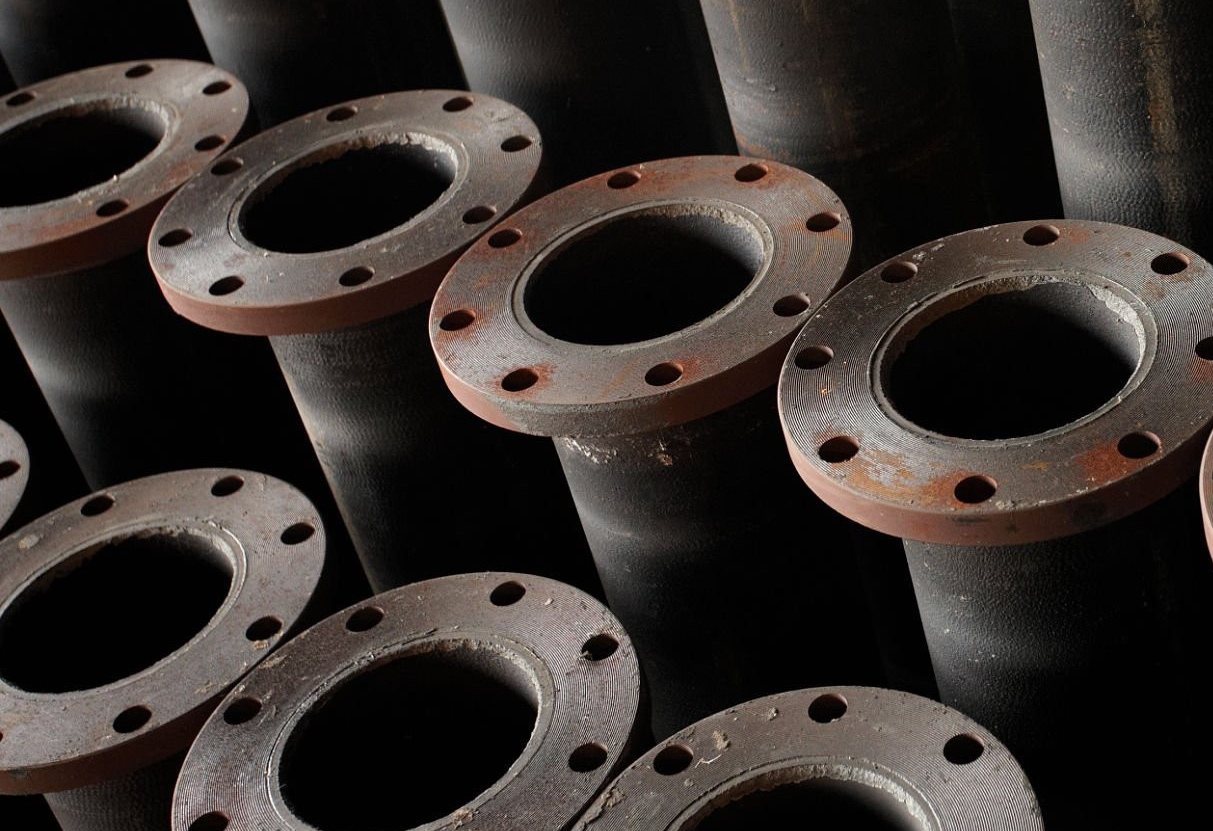

How is it made? When we add magnesium to the molten iron, the graphite forms nodules instead of flakes. The resulting characteristic is ductility in this type of iron. Consequently, due to these properties, it has various applications. They include pipes and fittings, engine blocks and crankshafts, gears, etc.

Properties

One of the main advantages of ductile iron is its ductility and strength. These two factors allow it to be used in high-stress locations. Therefore, we see this type of ductile iron in automobiles, among others.

Disadvantages

The disadvantage is the lack of castability. Because it is tough, casting this iron and manufacturing it as required is more difficult than with other types of iron.

Ductile Iron vs. Cast Iron – Key Differences to Know

In this section, we will discuss the differences between cast iron and ductile iron.

Strength Properties – Ductile Iron vs. Cast Iron

The first difference we will consider is the strength of these irons. In terms of strength, ductile iron is a stronger and better choice than cast iron. Furthermore, this is one of the major reasons it is an important choice for industrial uses.

Cast iron can be brittle. What does this mean? It means cast iron can fracture under stress. Yes, due to its lack of ductility, cast iron cannot bend without breaking. Therefore, ductile iron is always preferred over cast iron because of its higher ductility.

Thus, a key difference lies in ductility, where ductile iron offers more. Another major point to consider is tensile strength. Ductile iron has higher tensile strength than cast iron.

Structural Properties – Ductile Iron VS Cast Iron

There is a significant difference in structural properties. Where does this difference come from? Well, the difference is due to the internal structure of the graphite.

In ductile iron, spherical graphite nodules form during the manufacturing process. Consequently, this structure gives ductile iron amazing strength and ductility. How does cast iron differ in this aspect? Well, it’s because it has a flake graphite structure. This way, cast iron does not gain ductility and becomes brittle. Thus, this is how these two irons differ.

Other Properties – Ductile Iron VS Cast Iron

Are there other differences between cast iron and ductile iron? Yes! The differences lie in impact resistance, machinability, and corrosion resistance. How do these factors make an impact?

- Ductile iron has better impact resistance. This is because of its ductility. It provides amazing resistance. Therefore, ductile iron is ideal for high-stress applications.

- The next aspect of difference is machinability. In this regard, cast iron outperforms its counterpart. This is because of the structural properties we discussed earlier. Due to the flake graphite structure, machining cast iron is much easier than machining ductile iron.

- Both types possess top-class corrosion resistance. However, when we compare them, ductile iron holds a higher advantage over cast iron.

Applications – Ductile Iron vs. Cast Iron

Their applications also differ.

Pressure Handling:

Ductile iron is an ideal type for handling pressure. Its strength makes it suitable for pipes and valves. In all applications requiring handling high pressure, ductile iron is present. So why not use cast iron? Well, cast iron is brittle and can crack under high pressure.

Components Handling High Stress:

Ductile iron is used when dealing with high stress. Where can we see this application? If we look at engine blocks, gears, or automotive components, the use of ductile iron is very prominent. Why not use cast iron? Cast iron does not have enough strength to withstand excessive pressure or stress. Therefore, because ductile iron has the ability to withstand stress, it is used.

However, cast iron is used in applications like vibration damping. Why? The flake graphite structure of cast iron makes it an ideal candidate. We also see the use of cast iron in areas like manual equipment, pipe fittings, and agricultural equipment.

Other Differences

Are there other differences between ductile iron and cast iron? Let’s discuss other factors like cost, weight, and castability.

- Cost is one of the major differences between the two irons. Ductile iron is more expensive than cast iron. This difference arises because it offers better ductility.

- Castability is a property that allows iron to be molded into different shapes. So, which iron is better? Cast iron performs better due to its lower melting point and better fluidity. Therefore, because of these properties, cast iron is chosen over ductile iron for castability.

- Another aspect we must recognize is weight. Which of these two irons is heavier than the other? Ductile iron is heavier than cast iron due to the density of its structure. Furthermore, you should note that we are comparing components of the same size.

Thus, these are all the points of difference between these types of iron.