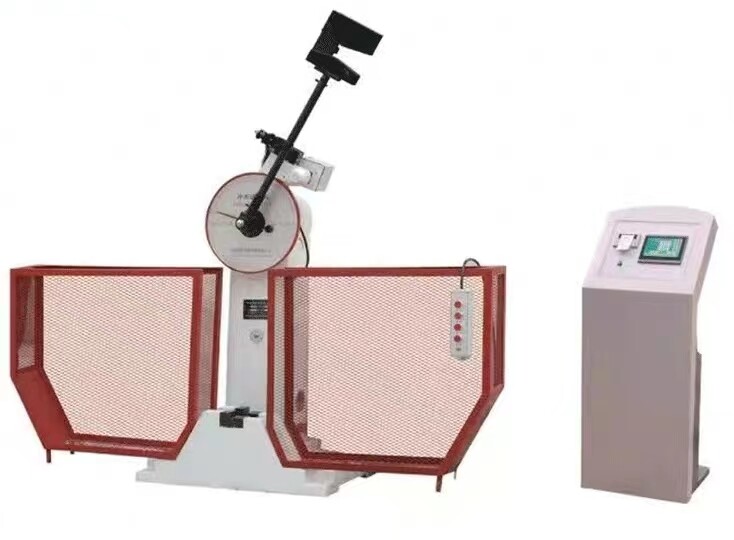

This machine is mainly used to test the impact resistance performance of metal materials under dynamic load. It is an indispensable testing instrument for metallurgy, machinery manufacturing and other units, and it is also an indispensable testing instrument for scientific research units to conduct research on new materials. This series of models is also The most common impact testing machine on the market at present.

Equipment Name:

Microcomputer screen display automatic impact testing machine

Model:

300J

Performance Description:

This machine is mainly used to test the impact resistance performance of metal materials under dynamic load. It is an indispensable testing instrument for metallurgy, machinery manufacturing and other units, and it is also an indispensable testing instrument for scientific research units to conduct research on new materials. This series of models is also The most common impact testing machine on the market at present.

◆This machine is a microcomputer screen display semi-automatic impact testing machine, which is controlled by PC microcomputer, which can realize microcomputerized operations such as swing→shock→measurement→calculation→screen digital display→printing, etc., with high work efficiency and high test accuracy. After impacting the sample, it uses the remaining energy to automatically swing to prepare for the next test. The operation is simple and the work efficiency is high. Its superiority can be manifested especially in laboratories where impact tests are performed continuously and industries such as metallurgy and machinery manufacturing where a large number of impact tests are performed. The computer can calculate and digitally display the impact energy absorbed by the material, the lift angle of the pendulum and the average value of the test. Remote data transmission can also be realized according to user needs.

◆The pendulum is designed as a U-shaped pendulum, which ensures the accuracy of the striking center and the precise moment of the pendulum;

◆The impact knife is installed and fixed by screws, which is easy and convenient to replace;

◆Equipped with a safety protection pin and equipped with a fully enclosed protective cover;

◆Microcomputer control, according to the command to complete the whole process of pendulum taking, impact, automatic swing, and impact multiple times.

◆The testing machine is equipped with a force sensor and an angular displacement sensor, which has high-speed sampling, storage and calculation functions;

◆The testing machine conforms to the national standard GB/T3803-2002 “Inspection of Pendulum Impact Testing Machine”, and performs impact tests on metal materials according to the national standard GB/T229-2007 “Metal Charpy Notch Impact Test Method”

The Main Technical Indicators:

|

Impact Energy |

150J, 300J |

|

Pendulum Prelift Angle |

150° |

|

Distance from the Center of the Pendulum Axis to the Impact Point |

750mm |

|

Impact Speed |

5.2m/s |

|

Span of Sample Support |

40mm |

|

Jaw Fillet |

R 1-1.5mm |

|

Impact Blade Fillet |

R 2-2.5mm R 8mm |

|

Impact Knife Thickness |

16mm |

|

Angle Accuracy |

±0.1° |

|

Sample Size |

10 (7.5, 5) × 10 × 55mm |

|

Dimensions |

650mm×1960mm×2100mm |

|

Net Weight of the Testing Machine |

About 550Kg |

|

Power Supply |

AC three-phase 380V±10% 50HZ 5A |

|

Environmental Conditions |

There is no corrosive medium in the surrounding environment, no vibration, no strong electromagnetic field interference. |

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.