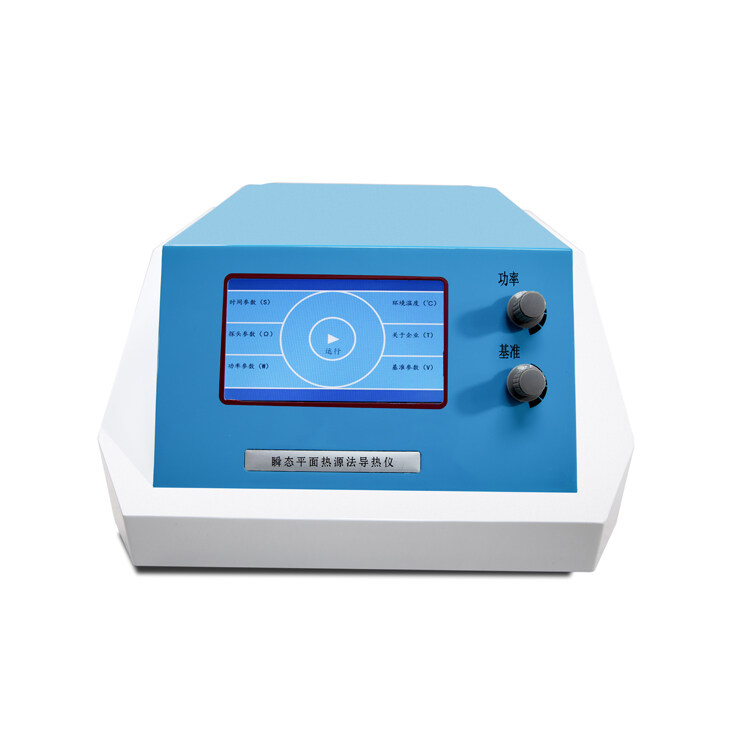

ZL-3044C is a thermal conductivity tester developed by using transient plane heat source technology (TPS), which can be used to test the thermal conductivity of different types of materials. Transient plane heat source method is one of the latest methods to study heat conduction performance, which makes the measurement technology reach a new level. The thermal conductivity can be measured quickly and accurately when studying materials, which provides great convenience for enterprise quality control, material production and laboratory research. The instrument is easy to operate and easy to understand. It will not damage the sample.

Introduction:

ZL-3044C is a thermal conductivity tester developed by using transient plane heat source technology (TPS), which can be used to test the thermal conductivity of different types of materials. Transient plane heat source method is one of the latest methods to study heat conduction performance, which makes the measurement technology reach a new level. The thermal conductivity can be measured quickly and accurately when studying materials, which provides great convenience for enterprise quality control, material production and laboratory research. The instrument is easy to operate and easy to understand. It will not damage the sample.

Working principle:

Transient plane heat source (TPS) is a new method for measuring thermal conductivity, which was developed by Professor Silas Gustafsson of Chalmer University of technology in Sweden on the basis of hot wire method. The principle of measuring the thermophysical properties of materials is based on the transient temperature response produced by the step heating disk heat source in infinite medium. A planar probe made of thermal resistance material is used as heat source and temperature sensor at the same time. The relationship between thermal resistance coefficient temperature and resistance is linear, that is, the heat loss can be known by understanding the change of resistance, which reflects the thermal conductivity of the sample.The probe in this method is a continuous double helix structure sheet formed by etching conductive alloy. The outer layer is a double-layer insulation protection layer with very thin thickness, which makes the probe have a certain mechanical strength and maintain the electrical insulation between the probe and the sample. During the test, the probe is placed in the middle of the sample for testing. When the current passes through the probe, a certain temperature rise is generated, and the heat generated diffuses to the samples on both sides of the probe at the same time. The speed of thermal diffusion depends on the thermal conductivity of the material. By recording the temperature and the response time of the probe, the thermal conductivity can be directly obtained from the mathematical model.

Test object:

Metals, ceramics, alloys, ores, polymers, composite materials, paper, fabrics, foamed plastics (surface insulation materials, sheets), mineral wool, cement wall, glass reinforced composite board CRC, cement polystyrene board, sandwich concrete, FRP panel composite sheet, paper honeycomb, panel, colloid, liquid, powder, granular and paste solid, etc., are widely tested.

Instrument features:

Main Technical Parameters:

|

Test range |

0.005-300 w / (m * k) |

|

Temperature range |

room temperature – 130 ℃ |

|

Probe diameter |

No.1 probe 7.5mm |

|

No.2 probe 15mm |

|

|

No.3 probe 30mm |

|

|

Accuracy |

± 3% |

|

Repeatability error |

≤ 3% |

|

Measurement time |

5 ~ 160 seconds |

|

Power supply |

AC 220 V |

|

Overall power |

< 500W |

|

Sample temperature rise |

< 15 ℃ |

|

Test sample power P |

No.1 probe:0 < p < 1W |

|

No.2 probe:0 < p < 14W |

|

|

No.3 probe:0 < p < 14W |

|

|

Sample specification |

Single sample measured by No.1 probe (15 * 15 * 3.75mm) |

|

Single sample measured by No.2 probe (30 * 30 * 7.5mm) |

|

|

Single sample measured by No.3 probe (60 * 60 * 20mm) |

Note: Probe No. 1 measures thinner low-conductivity materials, Probe No. 2 is a conventional general-purpose probe, and Probe No. 3 measures higher-conductivity materials with a larger thermal conductivity. If the surface of the sample to be measured is smooth and sticky, the samples can be stacked.

Compared with other methods, it is faster, simpler and more comprehensive:

|

Content |

Transient plane source method |

Laser method |

Heat flow meter method |

Protective plate method |

|

measuring method |

Unsteady state method |

Unsteady state method |

Unsteady state method |

Unsteady state method |

|

Measuring physical properties |

The thermal conductivity and thermal diffusivity can be obtained directly |

The thermal diffusivity and specific heat are obtained directly, and the thermal conductivity is calculated by the input sample density |

Obtain the thermal conductivity directly |

Direct thermal conductivity |

|

Scope of application |

Solids, liquids, powders, paste, colloids, particles |

solids |

Solids, liquids |

solids |

|

sample preparation |

No special requirements, simple sample preparation |

Sample complexity |

Simple sample preparation with specific requirements |

Larger sample size |

|

Measurement accuracy |

± 3%, preferably ± 0.5% |

± 10% |

±5% |

±3% |

|

physical model |

Plane heat source contact measurement, as long as the finite surface contact is good |

Non contact heat source |

The line heat source must be in good contact with the line model |

Heat source contact type, good surface contact is required |

|

Test scope[w/(m*k)] |

0.005-300 |

10-500 |

0.005-10 |

0.005-5 |

|

Measuring time |

5-160S |

A few minutes |

Dozens of minutes |

Few hours |

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.