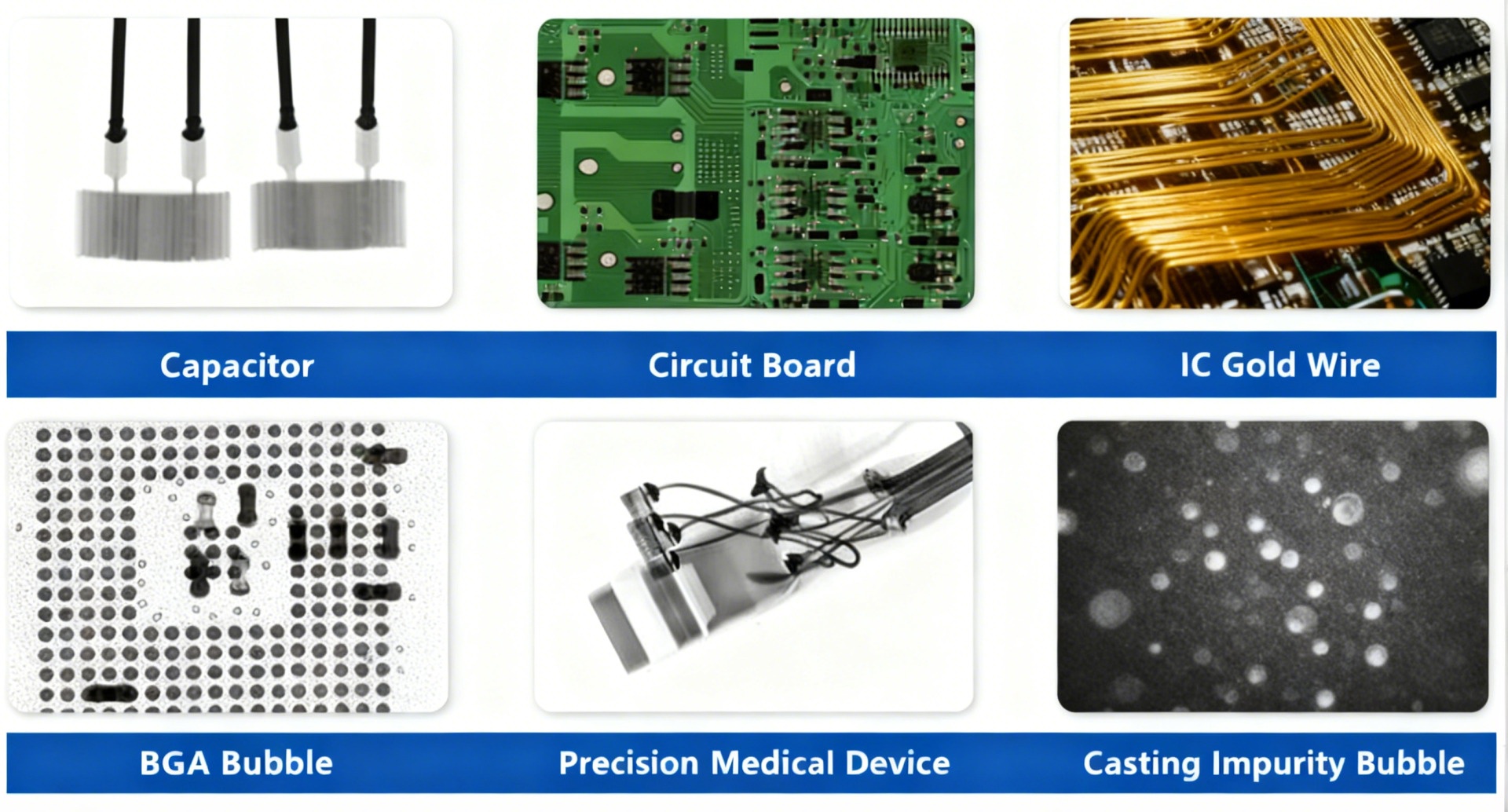

X-ray inspection equipment is mainly applied in the following professional fields:

1.Electronic manufacturing and semiconductor industry

In the production of integrated circuits (IC), printed circuit boards (PCB), and electronic components (such as capacitors, inductors, and connectors), real-time X-ray imaging technology is utilized It can accurately detect internal packaging defects of chips (such as poor gold wire bonding, voids in plastic encapsulation layers), PCB solder joint quality (false soldering, bridging, insufficient solder), and internal structural abnormalities of semiconductor packaging (such as chip offset, package cracking), meeting the quality control requirements for “zero defects” of precision electronic components in fields such as consumer electronics and industrial electronics.

2.The automotive and auto parts industry

For key automotive components (such as engine blocks, transmission valve bodies, and sensor housings), the penetrating power of X-rays is utilized to detect internal pores, cracks, and inclusion defects. For automotive electronic modules (such as on-board PCBS and sensor modules), the reliability of soldering and the integrity of the internal structure can be inspected to ensure the safe operation of the entire vehicle’s electrical system, meeting the strict requirements of the IATF16949 quality management system in the automotive industry for component testing.

3.New energy (lithium battery/photovoltaic) industry

In the field of lithium batteries, inspecting the alignment of the electrode sheets of power battery cells, the wrinkles of the separator, internal short-circuit hazards (such as metal foreign objects piercing the separator), and the welding quality of the cells in the PACK is one of the core devices for “safety performance verification” of lithium batteries from the research and development to mass production stage.

In the photovoltaic field: Non-destructive testing is conducted on hidden cracks, fragments of photovoltaic cells and modules, as well as internal bubbles and foreign objects in the packaging layer to ensure the power generation efficiency and service life of photovoltaic products.

4.Aerospace and high-end manufacturing industries

In the production of aerospace precision components (such as aero engine blades and hydraulic system components), detect internal microscopic defects (such as abnormal grains and microcracks); For high-end industrial castings (such as valves and pump bodies), casting defects (shrinkage cavities, sand holes) are inspected to ensure the reliability and safety of high-end equipment.

This type of equipment, with its high-resolution X-ray imaging and digital detection and analysis system, has become a key technical device for various industries to achieve “full-process quality traceability” and “precise defect control”.

Application Field:

X-ray inspection equipment is mainly applied in the following professional fields:

1.Electronic manufacturing and semiconductor industry

In the production of integrated circuits (IC), printed circuit boards (PCB), and electronic components (such as capacitors, inductors, and connectors), real-time X-ray imaging technology is utilized It can accurately detect internal packaging defects of chips (such as poor gold wire bonding, voids in plastic encapsulation layers), PCB solder joint quality (false soldering, bridging, insufficient solder), and internal structural abnormalities of semiconductor packaging (such as chip offset, package cracking), meeting the quality control requirements for “zero defects” of precision electronic components in fields such as consumer electronics and industrial electronics.

2.The automotive and auto parts industry

For key automotive components (such as engine blocks, transmission valve bodies, and sensor housings), the penetrating power of X-rays is utilized to detect internal pores, cracks, and inclusion defects. For automotive electronic modules (such as on-board PCBS and sensor modules), the reliability of soldering and the integrity of the internal structure can be inspected to ensure the safe operation of the entire vehicle’s electrical system, meeting the strict requirements of the IATF16949 quality management system in the automotive industry for component testing.

3.New energy (lithium battery/photovoltaic) industry

In the field of lithium batteries, inspecting the alignment of the electrode sheets of power battery cells, the wrinkles of the separator, internal short-circuit hazards (such as metal foreign objects piercing the separator), and the welding quality of the cells in the PACK is one of the core devices for “safety performance verification” of lithium batteries from the research and development to mass production stage.

In the photovoltaic field: Non-destructive testing is conducted on hidden cracks, fragments of photovoltaic cells and modules, as well as internal bubbles and foreign objects in the packaging layer to ensure the power generation efficiency and service life of photovoltaic products.

4.Aerospace and high-end manufacturing industries

In the production of aerospace precision components (such as aero engine blades and hydraulic system components), detect internal microscopic defects (such as abnormal grains and microcracks); For high-end industrial castings (such as valves and pump bodies), casting defects (shrinkage cavities, sand holes) are inspected to ensure the reliability and safety of high-end equipment.

This type of equipment, with its high-resolution X-ray imaging and digital detection and analysis system, has become a key technical device for various industries to achieve “full-process quality traceability” and “precise defect control”.

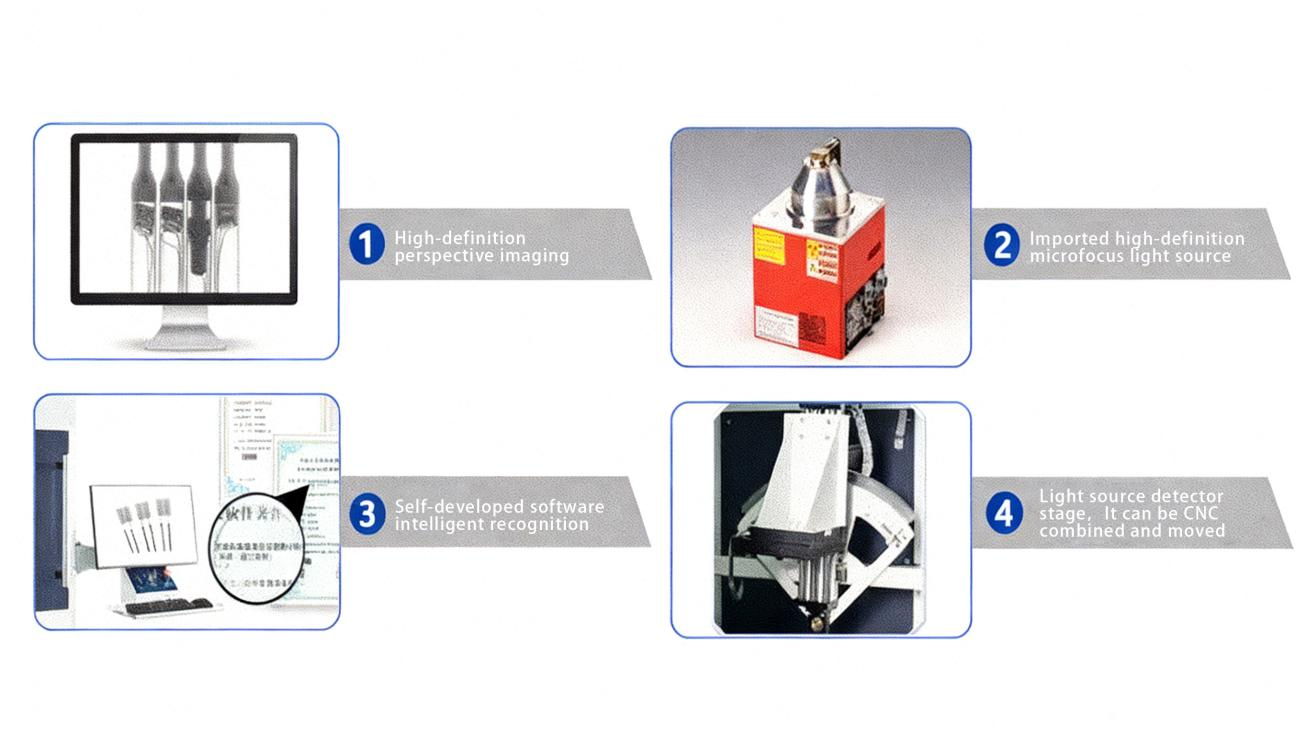

Features:

1.High-definition perspective imaging

2.Imported high-definition microfocus light source

3.Self-developed software intelligent recognition

4.Light source detector stage.It can be CNC combined and moved

Radiation safety

The radiation level of the entire machine complies with international standards, and the equivalent rate of the tested radiation dose on the surface of the entire machine is less than 1uSv/hr. Safety interlock function: Limit switches are set at all door opening positions. When the door is opened, the radiation source will automatically shut off. The automatic protection function of the radiation source: When the equipment is not in operation, the radiation source will automatically cut off power after 5 minutes and enter the protection state. The working status of the radiation source is indicated by a status indicator light.

Imaging Effect

Related Parameters:

|

X-ray Source |

Model |

ZL-4009-G740 |

ZL-4009-G750 |

ZL-4009-G751 |

||

|

Type |

Closed type |

Closed type |

Closed type |

|||

|

Optical tube voltage |

90kv |

90kv |

130kv |

|||

|

X-ray tube current |

90 microns |

90 microns |

300μm |

|||

|

Maximum output power |

8W |

8W |

39W |

|||

|

Focus size |

5-15um |

5-15um |

5-15um |

|||

|

Imaging Unit |

Pixel size |

85um |

||||

|

Pixel matrix |

1536×1536 |

|||||

|

Imaging area |

130.56mmX130.56mm |

|||||

|

Maximum spatial resolution |

5.5LP/mm |

|||||

|

Imaging speed |

1-7S |

|||||

|

Overall machine Parameters |

Overall machine dimensions |

970mm(L)*1720mm(W)*1810mm(H) |

||||

|

Overall weight of the machine |

800KG |

|||||

|

Overall machine power |

250W |

|||||

|

Power supply |

AC110-240V 50/60Hz |

|||||

|

Operating temperature |

0-50℃ |

|||||

|

Motion control System

|

Loading area |

600mmx570mm |

||||

|

Detection area |

130mmx130mm |

|||||

|

The load capacity of the stage |

≤10kg |

|||||

|

Mobile control mode |

|

Three-link operation of joystick, mouse and keyboard |

Three-link operation of joystick, mouse and keyboard |

|||

|

Tilt Angle |

The maximum rotation Angle of the swing arm is 60° |

|||||

|

Computer |

Industrial control computer |

Industrial computer |

||||

|

Operating system |

Windows10 64-bit |

|||||

|

Display mode |

24-inch monitor |

|||||

|

|

Intelligent image algorithm |

The brand-new generation of HD image enhancement engine makes X-Ray imaging clearer |

||||

|

Diversified measurement tools |

It can measure distance, Angle, circle, area and curvature. The tinker ratio is measured and text can be freely inserted |

|||||

|

BGA bubble detection |

Quickly identify BGA solder balls and automatically calculate the void ratio.It requires less parameter adjustment, has strong anti-interference ability and high accuracy |

|||||

|

Multiple operation methods |

Double-click the center function of the screen to facilitate personnel operation |

|||||

|

Defect marking |

Supports simultaneous marking of X-rays and visible light, with multiple intuitive marking ICONS for convenient defect classification and re-judgment |

|||||

|

Multi-angle testing |

When performing a tilt operation or zooming in a tilted state, the image of the target object automatically follows |

|||||

|

One-click invocation of configuration parameters |

Based on the product features and the best test results, export, save and call the parameter templates |

|||||

|

CNC automatic inspection |

It can easily achieve multi-point positioning detection, with simple programming and multiple programming methods |

|||||

|

Permission management |

It has a two-level permission management system, including operator and administrator permissions |

|||||

|

Detection System |

AI detection capability |

It integrates AI detection functions. Through CNC automatic positioning, AI algorithms automatically identify defects, and the algorithm discrimination results are visually presented on the software interface. Images and inspection reports are automatically stored |

||||

|

Flexible configuration of algorithms |

Equipped with AI intelligent algorithms, it can detect defects such as false soldering, continuous soldering, bubbles, foreign objects, and missing components, and supports algorithm customization for special detection scenarios |

|||||

|

MES connection |

The test results are displayed in real time, and the data and photos are uploaded to the MES or database in real time |

|||||

|

Data statistics |

The defect rate and quantity of the products are automatically statistically displayed |

|||||

|

Automatic scanning code |

Our self-developed automatic scanning technology features high accuracy and strong adaptability, capable of detecting QR codes as small as 2mm |

|||||

|

Rejudgment mode |

After the product inspection is completed, the results can be rejudged |

|||||

|

Navigation System |

Camera configuration |

The picture is high-definition and the visual operation experience is excellent |

||||

|

Automatic navigation function |

Precise and accurate in one step, facilitating quick and convenient movement to the detection target |

|||||

|

Magnification function |

It can achieve a maximum field of view magnification of 400 times |

|||||

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.