ZL-5006 Martindale tester is a standardized method for assessing a material’s durability, abrasion resistance, and overall wear performance. During the test, a rotating disk fitted with an abrasive medium—such as sandpaper, wire mesh, or worsted wool—moves in a figure-eight motion across the material’s surface. The number of cycles completed before visible wear appears serves as a measure of the fabric’s wear resistance and long-term durability.

This article goes into more detail about the Martindale test, its purpose, the materials that are tested, and the standards that apply to this test.

What is the Martindale Test?

ZL-5006 Martindale Tester is a standardized abrasion resistance testing method widely used in the textile industry, named after its inventor, Dr. Martindale. This test evaluates the wear resistance of fabrics, leather, and other flexible materials by simulating friction and abrasion under everyday use conditions. The Martindale testing machine has become an essential tool for global textile quality control, particularly in sectors such as upholstery fabrics, apparel materials, and industrial textiles.

What Are the Features of the Martindale Test?

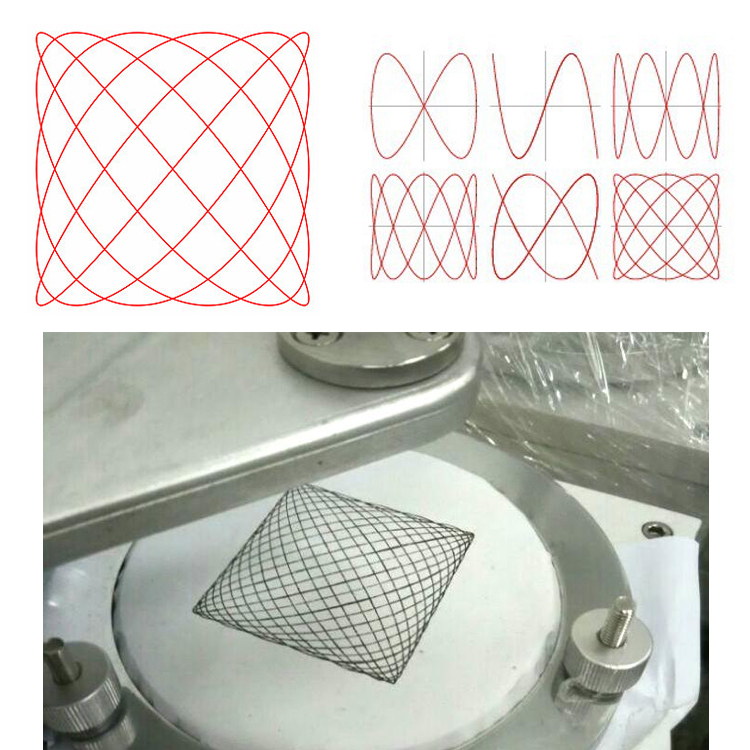

Utilizes the Lissajous curve movement pattern to ensure continuous variation in friction direction, accurately simulating real-world usage conditions.

Adjustable Pressure System:

Allows precise pressure adjustment on test specimens to meet different standard requirements.

Multi-Station Design:

Martindale testers feature 4-9 testing stations, enabling simultaneous evaluation of multiple samples for enhanced efficiency.

Automatic Cycle Counting:

Automatically stops testing upon detecting yarn breakage or when reaching preset friction cycles.

Precision Mechanical Structure:

Ensures consistent movement trajectory and applied pressure across tests, guaranteeing highly repeatable results.

What Is the Purpose of the Martindale Tester?

The main purpose of a Martindale tester is to test for fabric pilling and the abrasion resistance of textiles. This means that it is used to test the durability of fabrics.

How to Interpret Martindale Test Results?

ZL-5006 Martindale abrasion tester evaluates fabric durability by subjecting materials to controlled friction using standardized abrasive media, including sandpaper, worsted wool, or wire mesh discs. The resulting Martindale rating quantifies a fabric’s abrasion resistance, with higher numerical values indicating superior durability. This rating represents the exact number of rubbing cycles the material withstands before exhibiting measurable wear, as determined by either:

Visible surface degradation (yarn breakage, pilling, or hole formation)

Structural failure thresholds specified in testing protocols

The test’s precision lies in its ability to simulate long-term wear through repetitive, measurable friction cycles under controlled laboratory conditions. Each abrasive medium (sandpaper for aggressive wear, wool for moderate testing, or wire mesh for specific applications) provides distinct wear patterns that correlate with real-world usage scenarios.

Abrasion Resistance Classification

Results are often categorized into durability grades (varies by industry standards):

|

Abrasion Cycles |

Grade |

Typical Applications |

|

10,000–15,000 |

Light Duty (Household) |

Curtains, lightweight apparel, bedding |

|

15,000–25,000 |

Medium Duty (Commercial) |

Office furniture, hotel upholstery, backpacks |

|

25,000–40,000 |

Heavy Duty |

Public transport seats, outdoor gear, industrial fabrics |

|

>40,000 |

Ultra-High Resistance |

Military textiles, high-performance sportswear |

What Type of Materials Are Tested With a Martindale Tester?

ZL-5006 Martindale tester can be used to test the following materials:Textiles ,Wood,Leather,Paper,Carpets,Coated upholstery.

Standards Compliant:

ISO12945-2, ISO12947, ASTM D4966, ASTM D4970, ASTM D3886,JISL1096,DIN 53863,DIN 53865, BS 3424, BS 5690,BS-EN388, BS-EN530,

BS-EN16094,GB/T21196, GB/T4802.2, GB/T13775, FZ/T20020, IWS Tm196/ TM112 M& S

Technical Parameters:

|

Station Number |

4 station (6 station , 8 station , 9 station can optional) |

|

Count Display |

a. Estimated counting:0~999999 times |

|

b. Total counting:0~999999 times |

|

|

Maximum Dynamic Range |

24±0.5mm ,60.5±0.5mm |

|

Weight of Pressure Thing |

a.Gripper:200±1g |

|

b. Cloth samples hammer:395±2g |

|

|

c. Furniture accessories sample hammer:594±2g |

|

|

d. Stainless steel butterfly piece:260±1g |

|

|

Effective Friction Diameter of Grinding Block |

A type: 200g (1.96N) friction head ¢ 28.8-0.084mm |

|

B type: 155g (1.52N) friction head ¢ 90-0.10mm |

|

|

The Relative Velocity of Gripper and the Grinding Station |

50-2r/min |

|

Weight of Pressure hammer |

2385±10g |

|

Dimensions |

885mm×600mm×410mm(L×W×H) |

|

Weight |

150kg |

|

Power |

AC220V,50Hz |

|

Amount of Pressurized Material

|

Weight: 9kpa 12kpa Sample fixing kit: 795g Cutter diameter: 38mm Effective friction diameter of grinding block: φ28.8mm Optional: Pilling device (effective friction diameter of grinding block: φ90mm) |

As the gold standard for evaluating textile abrasion resistance, the Martindale test has gained widespread recognition throughout the global textile industry for its scientific rigor and practical utility. Through standardized testing procedures and objective data