Verfahren zur Lösung des Problems der Gussporosität

Die Druckgussporen sind in Gussteilen weit verbreitet. Die Lösung der Lochfehler von Gussteilen war für viele Hersteller schon immer ein Kopfzerbrechen. Weil

Die Druckgussporen sind in Gussteilen weit verbreitet. Die Lösung der Lochfehler von Gussteilen war für viele Hersteller schon immer ein Kopfzerbrechen. Weil

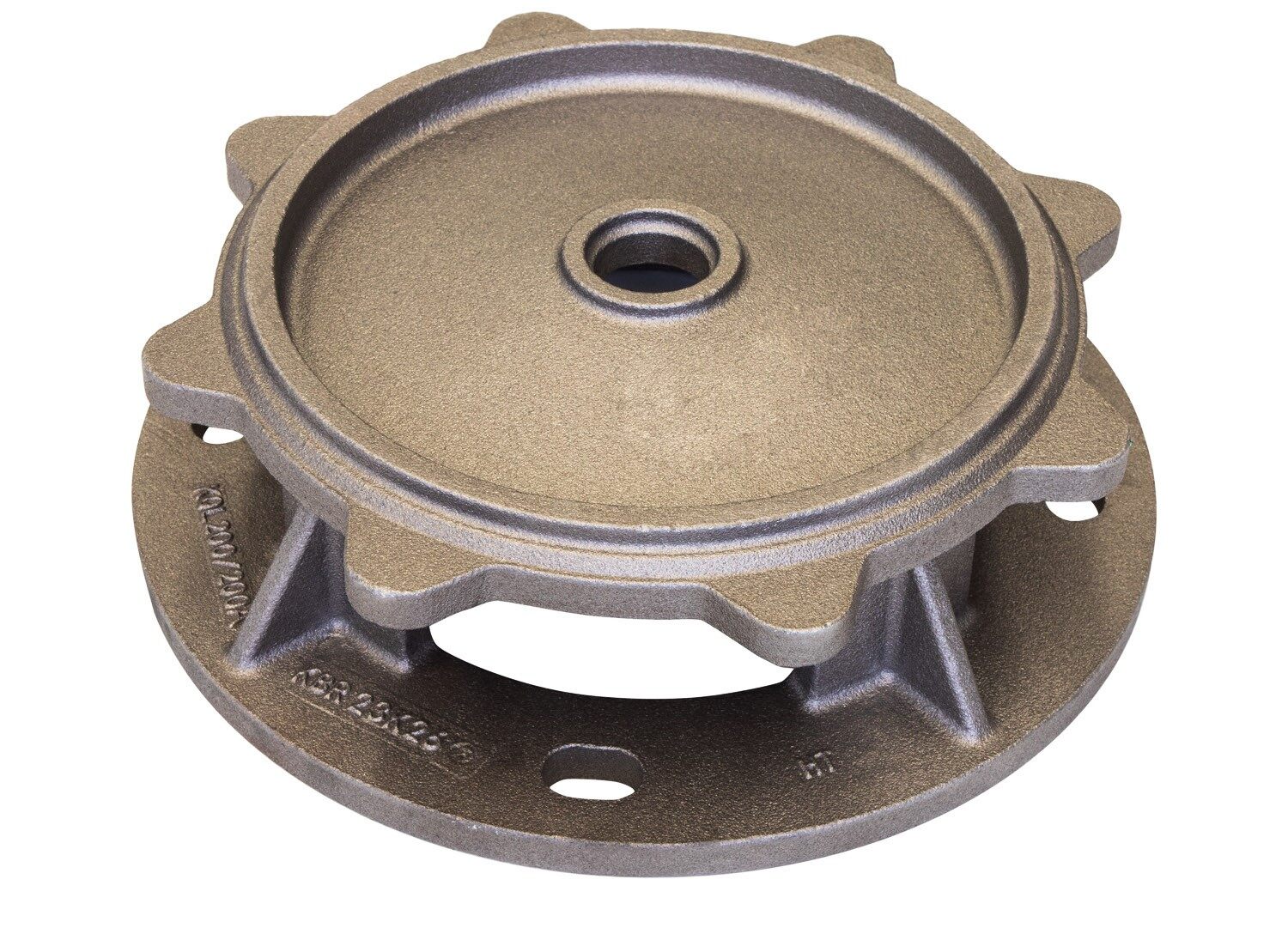

Die Hauptanwendungsgebiete von duktilen Gussteilen sind Elektronik und Elektrotechnik, Leichtindustrie, Lagerindustrie, Automobilteileindustrie und andere Teileverarbeitung, weil diese

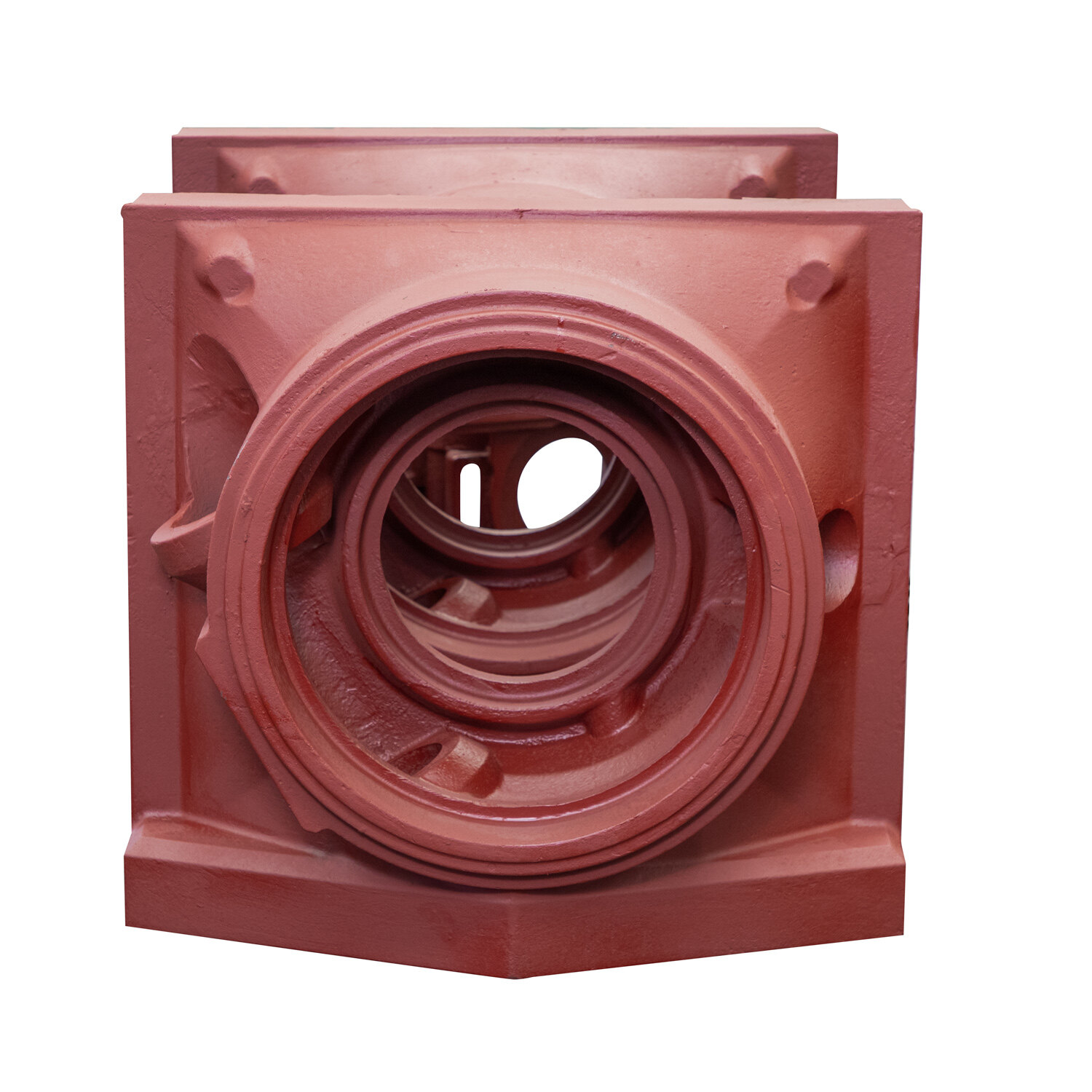

Bei großen Gussteilen besteht der grundlegendste Gesichtspunkt darin, das „thermische Gleichgewicht“ von Gussschrumpfungsfehlern zu lösen. Im Erstarrungsprozess großer

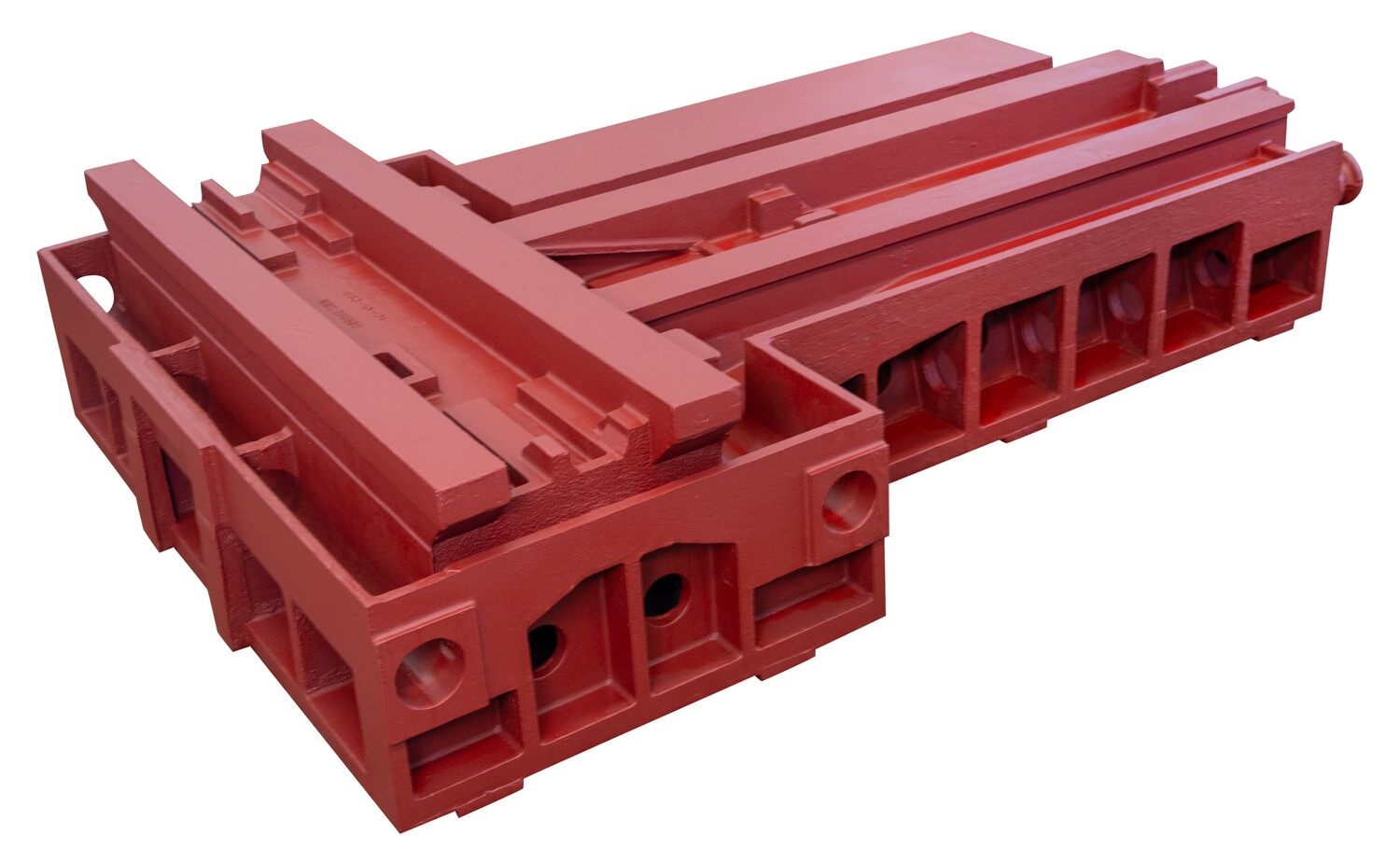

Graugussteile werden in verlorenen Formen und im Harzsandgussverfahren hergestellt und verfügen über große Gastemperöfen, künstliches Altern, Tempern und Lösen innerer Spannungen usw.

Gussteile aus Roheisen, deren Oberfläche oft uneben und porös ist, erhalten nur eine raue und poröse Beschichtung. Außerdem

Das Gießen ist die am weitesten verbreitete Methode. Dabei wird flüssiges Metall in eine Gussform gegossen und dann ein Rohling oder Teil erhalten.

Shanghai keboer Casting Group Co., LTD