Menu

Sfero döküm

- Home / Sfero dökümSfero döküm

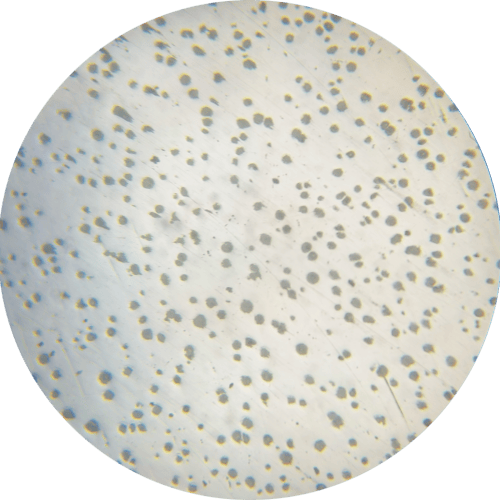

90% küreselleşme oranı

Sfero döküm metalografisi

Sfero döküm

Sıvı gri dökme demire nodüler ve aşılayıcı eklendiğinde, pulsuz grafit küresel grafit haline gelir ve bu da dökme demirin mekanik özelliklerini, özellikle plastikliğini ve tokluğunu önemli ölçüde iyileştirir.

Yüksek mukavemet, iyi tokluk, iyi aşınma direnci vb. özellikleri nedeniyle şaft, kaplin, dişli, pompa gövdesi, valf, silindir gövdesi gibi her türlü mekanik parçada yaygın olarak kullanılır.

Keboer Şirketi'nin ürettiği sfero dökümlerin küreselleşme oranı 90%'e kadar çıkabilmektedir.

90% küreselleşme oranı

Sfero döküm metalografisi

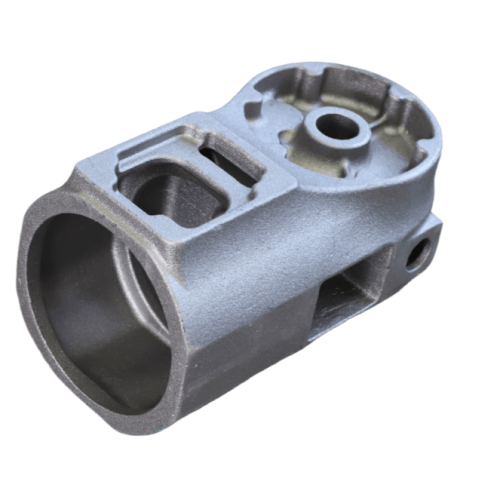

Motor – Konnektör

İşlem : Kaplamalı kum Ağırlık : 45Kg

Malzeme : QT400-10

Bağlantı

İşlem: kaplamalı kum

Ağırlık : 16Kg

Malzeme : QT500-7

Shanghai keboer Casting Group Co., LTD